- Leading Cable and Wire Manufacturer-ZW

- Medium Voltage Cables

Medium Voltage Power Cable

- According to IEC, GB and BS Standard

- Flame Retardant & LSZH Cable

- Approved by ISO, CE, SGS

- Large stock 15kv cables with different sizes

Medium voltage power cable is suitable for ground. XLPE material has excellent insulation properties and is firmly spliced with conductor and insulation screens of semiconductor material, so this cable has high reliability. It is suitable for substations, power plants and industrial plants.

Conductor: stranded circular compacted tinned copper, IEC 60228, class 2

Conductor screen: semiconducting material

Insulation: HF EPR or XLPE

Insulation screen: semiconducting a material + copper tape

Filler if necessary

Polyester Tape

Inner covering: thermoplastic polyolefin halogen-free compound, PO SHF1

Amour: TCWB or GSWB

Outer Sheath: thermoplastic polyolefin halogen-free compound, PO SHF1

Color of outer sheath: Red

Conductor Material: Copper

Conductor Screen: Semi-Conductor Polymer

Insulation: XLPE

Insulation Screen: Semi-Conductor Polymer

Metal Screen: Copper tape

Insulation Sheath: PVC

ZW medium voltage Cable specialist provides cable technology and advice

A medium voltage (MV) cable is appropriate for power frequency-rated voltage distribution systems ranging from 6-35KV. It is also suitable for various environments, including high average operating temperatures. It is also easy to use due to its simple structure, small outer diameter, lightweight, and lack of a laying drop.

Furthermore, the medium voltage cables use a dry chemical cross-linking method. This cross-linking method employs polyethylene molecules that are linearly inserted into a spatially reticulated structure.

It also entails converting the thermoplastic polyethylene molecular structure into thermosetting cross-linking polyethylene. As a result, the medium voltage cable has excellent mechanical, electrical, and heat aging properties.

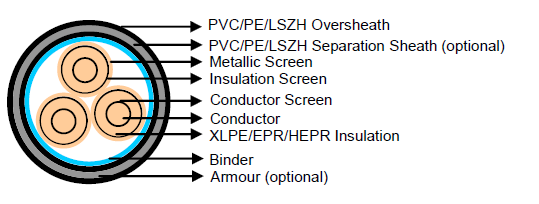

MV Cable: Construction

In the design and construction of medium voltage cable manufacturers, all that matters is the MV cable layers and materials.

Conductors | It comprises copper or aluminum materials falling under Class 1 solid and International Electronical Commission (IEC) Class 2. Circular compacted- A round conductor with all layers stranded in the same direction and rolled to a preset ideal form is called a compact stranded conductor. The final conductor has a smooth surface and almost no interstices or air gaps. As a result, the diameter is reduced. |

Conductor Shielded | Semi-Conductive Layer offers a shield, which can help the conductor and insulation layer contact tightly and minimize the interfacial gap. It exists between the wire core and the insulation layer. |

Insulation | Cross-linked Polyethylene (XLPE) and Ethylene Propylene Rubber (EPR). |

Insulation Screen | It consists of a partly-conveyed amalgam. |

Metallic Screen | It’s composed of copper lines or wires that are placed on each of the cable’s cores |

| Armoured | Its material is divided into two parts. Steel Tape and Steel Wire. |

| Outer Sheath | It comprises resistant films like Low Smoke Zero Halogen (LSZH), Low/Medium Density Polyethylene (LDPE/MDPE), & Polyvinyl Chloride (PVC). |

Medium Voltage Cable Standards

To get a medium cable certification, it’s crucial to understand the cable product standards. Usually, they are in medium-voltage cable standard form, and the MV quality description is as follows:

XLPE Medium Voltage Cable Standard | Medium-Voltage Standard Description |

BS 6622 | A standard is qualified to handle medium-voltage armored cable with LSZH exterior shielding and electromotive force grading from 6kV-33kV. |

It’s described as one core cable for issuing energy with ejected cover up to plus 15kV cable and 33kV | |

DIN VDE 0276 | It’s the counting cable of minimal electromotive forces 3.6 – 36kV |

Power cables product with ejected cover incorporating voltage range of 6kV and 30kV |

Medium Voltage Cable Types

Medium voltage cables are manufactured in different sizes . Unlike low voltage cable or high voltage cables, our medium-voltage cable suppliers usually supply 10kV, 11kV, 20kV, 22kV, 30kV, and 33kV.

Medium Voltage wire is obtainable and affordable in various cross-sectional sizes are Copper or Aluminium conductors.

10kV cable | Single core is between 35-300mm2 & three cores 35-240mm2 |

11kv cable | The individual one sizing between 25-630mm2 and three cores going for 35-300mm2 |

20kv cable | 20kV goes for 30-500mm2 size in a single-core cable and 35-630mm2 for a three-core medium-voltage wire |

22kV cable | Its single core is 35-630mm2, while a three-core is 50-500mm2 |

30kV cable | It comes only in the measurements of one core 50-500mm2 |

33kv cable | The single core stands between 70-800mm2, and the three cores go for 50-400mm2 |

Other than the above list, two single types also fall under the basis of medium-voltage cable sizes:

- The MV 105 Cable. It’s a one conductor medium voltage cable special for application up to size 15kV.

Ideally, it’s kept where compressed extent, a diminutive buckle range, or ambitious fixing is experienced.

- The other one is the MV 9O Cable. It’s an imperative electrical wired utilized for utility circuits up to 15000 volts when installed in external air space, conduit/tube.

Medium voltage cable uses in energy substations, chemicals, generating stations, plant refineries, etc.

Medium Voltage Cable Specifications

Depending on uses, the prices of medium voltage cables may differ, such as 11kV cable or 15kV medium-voltage cable.

But the lifespan and durability of a particular initiation of a power product you need matters. Supposedly, it should match and meet your expectation and requirements.

Besides, our products are easy to insulate cables and have excellent specifications.

- They are obtainable with durable materials like copper & aluminum conductors.

- They are checked and structured per the current IEC, HD, or BS worth.

- You can get Cross-linked Polyethylene (XLPE) medium voltage armored cable isolation.

- Our expert team ensures they are accessible with copper wires/strip metallic screens with customized short-circuit current capacity.

- We provide medium voltage power products both in Armoured or Non-armoured constructions.

- Watertight designs are available upon your appeal.

- They are also provided with a fire-retardant PVC jacket to pass the blaze spread assessment to IEC 60332-1.

Medium Power Cable Stockholding & Supply

In making the process of stockholding and supply cheap, our team of experts ensures that protocols are maintained. So, after you’ve identified and made the right construction and qualities, we can deliver your MV cable types as fast as possible. Usually, our company attends to all our customers by putting in place every critical measure needed.

Even if it’s an urgent requirement straightly from stock, produced, or executed the same day of order, it will still be delivered. Besides, our power cable products are obtainable at striking distances and at prolonged heights to ease installation.

Custom Designed Cable Medium Voltage

Usually, medium voltage cables are adapted to the installation to improve efficiency and increase longevity. In other construction environment situations, custom cables are necessary. Our medium-voltage cable experts can work with you to provide a solution that fits your needs. In addition, special applications may affect the use of certain cable properties. This may affect voltage drops and short-circuiting of currents.

In all cases, we make solutions available to our customers. Each step in the production process is rigorously tested (e.g., conductor resistance, insulation thickness, sheath thickness, etc.). Therefore the cable will be shipped only if it is guaranteed to be qualified.

The Electrical Testing for MV Cables

The purpose of these electrical performance tests is to ensure the long-term reliability of the cable. All completed cables are subjected to the most rigorous testing. Here are some of the items that are tested:

- Electrical resistance of the conductor

- High voltage test

- Measurement of partial discharges

- Outer-sheath dielectric testing

- Resistivity of insulation

- Tangent Delta insulation measurement

- Semi-conductor resistivity

- Long-term harmonized test (2 years)

- Thermal cycling test followed by partial discharges

- Longitudinal/radial blocking of the screen and/or the conductor

- Bending followed by partial discharges

Having these tests performed on our medium voltage cables, we guarantee you cables that are 100% acceptable. Consider yourself fortunate to have ZW cable as your go-to supplier for medium voltage cables.We can offer your best medium voltage cable price.