- Leading Cable and Wire Manufacturer-ZW

- Welding Cable

Welding Cable

- According to IEC 60502-1

- EPR, EPDM

- Approved by Rohs, CE, GB, IEC

- Large stock welding cables with different sizes

- Voltage 450/750v

Welding Cable Size

We can produce EPDM Cable, EPR Cable, and CPE Cable. We can produce AWG size like 1 AWG Welding Cable, 2 gauge welding wire. We can also IEC size like 25mm welding cable, 35mm welding cable, and 50mm welding cable, and 70mm welding cable.We have large cable in cable in stock. Contact Us Get your Best Rate

Your Welding Cable Guide: Choosing the right cable guarantees better welding performance

If you are here, on this site, then you likely need welding cable. Or, perhaps you have a welding project lined up, and are wondering whether you should use #2 welding cable, or if #4 welding cable is what you really need? You may even come across some charts, hoping to determine which is the right cable for your needs. Should you order 2 gauge welding cable, or would a 4 gauge welding wire be a better choice?

Regardless of what your reason is for coming to this page, we’re glad you came. In the next few sections of this welding cable wire guide, we’ll unravel the mysteries of everything related to these cables.

1)What is a welding cable?

Before we get into the more complex questions like what does welding cable size mean, how to differentiate between best welding cable vs battery cable – let’s understand the basics. First and foremost, let’s explain what a welding cable is?

It is a conductor for the electrical current (welding current) used is the welding process. Typically, it’s made of a number of thin copper strands, sheathed inside a durable, non-conductive jacket. Usually, the jacket is either made from synthetic material – for instance, a rubber cable will have a jacket made from rubber.

Depending on its type and use, the jacket may also be color coded for ease of identification. For instance, a red welding cable will have a red colored jacket to distinguish it from mistakenly used on an application requiring a different specification cable, which might have a black-colored sheathe.

2)What size welding cable do I need?

You’ll need to buy or use the most appropriate welding cable wire based on the application or project. And, whether a cable of a particular specification meets the projects’ objectives, depends on the welding cable size. Thinking of this (i.e., size of a cable) in terms of a common example might help clarify this concept.

Assuming you want to but a water hose, the size of that hose will depend on its application. To water your garden, you’ll need a hose with a smaller diameter. But if it’s a fire-fighting application, a hose with a larger diameter may be called for. The same is true when determining welding cable size, which hinges on the level of current, measured in AMPS (or amperage).

Welding cable ampacity, also known as the amperage rating or current capacity, of the welding cable wire determines the maximum amount of current that may safely conduct through the cable. This metric (AMP) has direct bearing on the size requirements of the cable. As you increase the level of current during the welding process, the diameter of the individual strands (also called the cross-sectional area), as well as that of the overall cable, expands. Therefore, a 125 AMP-rated wire will be thinner than a 200 amp welding cable.

The welding cable ampacity, and hence its size, also depend on some other factors, including:

- Resistance rating (or ohm rating)

- Ambient temperature

- Length of the welding cable

- Insulation material temperature rating

All these characteristics, when combined, work to determine the welding cable size. For instance, shorter cables of a specified diameter carry larger amounts of current than similar diameter lengthier cables.

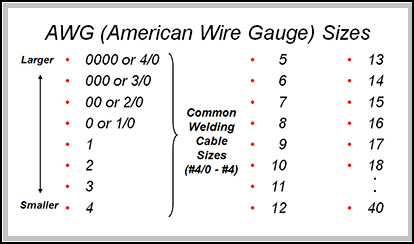

The industry typically categorizes cables by what’s known as an AWG (American Wire Gauge) size. The AWG rating works in inverse direction of the cable size. The larger the diameter of the cable, the smaller the AWG number.

Typically, the welding cable sizes fall in the range of #4 and #4/0. A 4 gauge welding cable is than a 3-gauge cable. Larger cable size is also determined by numbers smaller than 1. For instance, size 0 (also called 1/0, and pronounced as “one aught”) is smaller than “00” (also called 2/0, and pronounced as “two aught”). Both those sizes are larger than a 4/0 welding cable.

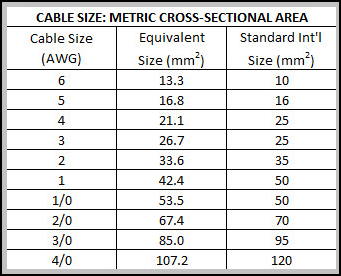

The cross-sectional area of a welding cable may also identify the size of the cable. This measure is sometimes expressed as square millimetres (mm2) in the metric scale. There are readily-available conversion charts that show welding cable size in both AWG size and sizes measured in mm2. For instance, in the chart above, when sizing a 2 gauge welding cable in mm2 rating, the equivalent standard international mm2 size is a 35mm welding cable.

To select the most appropriate size of welding cable for sale, for your welding machine, you’ll need to choose a cable that handles the maximum output of the welding equipment. And that depends on three significant factors:

- Rated output (AC or DC) of the welding machine’s power source

- The duty cycle of the welding machine’s power source; and

- Total length of the welding circuit

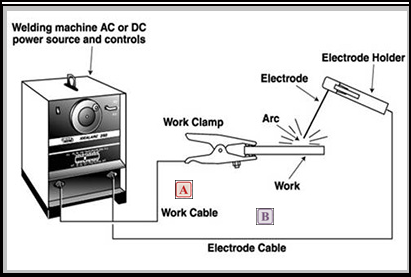

In this welding cable guide we’ve highlighted in the figure above, a sample welding circuit. If you have a set-up similar to the above diagram, you’ll need to add the total lengths of the Work cable (A) and the Electrode cable (B) to determine your proper welding cable size.

3)Where to buy welding cable by foot?

Sometimes, you might not be too familiar with various cable sizes in mm2. Instead, you know a few basic requirements of your cable and are wondering where can I buy welding cable near me, but by foot – instead of meters or other dimensional metrics.

Well, it’s easy to answer the “where” part of that question. Look for a reputable manufacturer of welding cable, like ZW Cable, and place your order online. It’s really that simple. Of course, before you settle on a cable supplier, whether it’s rubber cable that you are looking for or welding lead cable that you’re sourcing, check to ensure they are experienced and have a good reputation. Always source your cables from a supplier with a track record of producing high-quality cables and wires. And, of course, make sure the welding cable price they offer is competitive too!

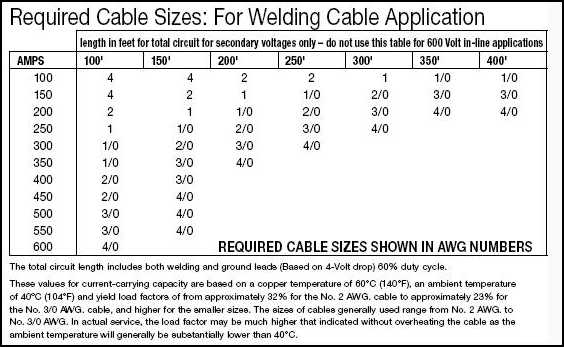

Now, how do you buy the right cable measured in foot? For that, you’ll need to refer to our welding cable guide chart above. So, how do you now determine how many feet of cable do you need to order, based on the chart? Well, assuming you are using a 400 AMPS power source at 60% duty cycle. You then do the math and add the total lengths of the Work cable (A) and the Electrode cable (B) to determine your proper welding cable size. You arrive at a figure of 100 feet.

So, what does that tell you about the required welding cable ampacity and size? To determine the right cable, here’s what you do:

- Moving vertically, top to bottom, locate your power source rating in the column labeled “AMPS” in the chart above (in our example that number is 400)

- Then, move horizontally – left to right, and go to the column identifying the number showing length (A + B) in the heading (In our example, that’s 100 feet)

- At the intersection of 400 AMPS and 100 feet, you’ll see the AWG rating of the cable you need – which corresponds to a 2/0 welding cable

So, for your application, you’ll need to order 100 feet of 2/0 welding cable. Conversely, if your welding machine is rated at 250 AMPS, and your combined Work cable plus Electrode cable length works out to be 150 feet, then you’ll order a 1/0 welding cable. It’s that simple!

Reputed cable manufacturers, like ZW Cable, typically offer high-quality welding cable for sale at extremely reasonable prices. And, if you’re unsure how much cable you require, by foot, based on the welding cable ampacity for your application, they’ll assist you to figure the specific lengths in feet as well.

4)Is welding cable different from battery cable?

Understanding the great debate about welding cable vs battery cable is always important when making decisions about which type of cable to source for a welding project. This welding cable guide discusses some critical aspects of similarity and differences between these two types of cables.

Based on their application, one might see welding cable and battery cable as similar; but there are differences in their construction. This, therefore, makes one type of cable more useful for specific applications compared to the other. It’s all relative!

If it’s a matter of simply establishing a connection between the battery and a starter, then a battery cable would win the debate around welding cable vs battery cable. However, if the application involves many twists, bends and turns to complete the wiring process, then flexible welding cable is what’s most appropriate.

Another point of difference to understand, in the great welding cable vs battery cable discussion, is related to the elements of nature. With its smooth thermoplastic polyvinyl chloride (PVC) jacket, battery cables are protected against extreme weather, cracking, acid damage and abrasion. That’s why they are UL-558 and UL-553 certified. However, the UL-1581 standards for welding cable means they have an additional level of protection – against fire and high temperatures.

5)Is welding cable OFC?

Let’s assume you’ve decided to buy 200 amp welding cable. Before you place an order, it would help to understand the two basic types of cables available for you to choose from. The two popular standards are Copper-clad Aluminum (CCA) and Oxygen-free Copper (OFC) cables. While you may source CCA cables, a reputable cable supplier will also offer you flexible welding cable that’s OFC.

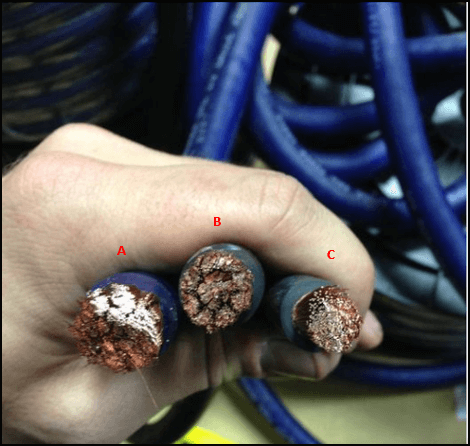

Based on the above picture, here’s what each of these three cables are:

A.2/0 OFC

B.1/0 OFC

C.2/0 Welding Cable

It’s hard to determine the pros and cons of CCA versus OFC cable by simply doing a cursory visual inspection. The welding cable price won’t tell you much either, because pricing varies based on length of the cable, the amperage rating and the AWG size of the cable you purchase. To determine if OFC cable is right for your application, you’ll need to consider the following two factors:

Firstly, the characteristics of aluminum is such that it only conducts 61% of the electric energy compared to that which copper conducts. This means that an 2/0 welding cable of CCA type will be only 61% as efficient as an OFC welding cable. Why? Because you’ll need a thicker CCA cable than its OFC equivalent – which means CCA will produce less heat, which makes it a better overall choice. You’ll need larger gauge CCA (1 to 2 times larger than CCA) to provide the same level of resistance that pure copper.

The second deciding factor is oxidization. OFC cables go through a process that removes many of the impurities that CCA cables possess. This makes OFC welding cable a better conductor that produces comparatively less resistance to electricity. Less resistance = more efficiency.

Obviously, because of the differences in manufacturing process most cheap welding cable may be CCA type.

6)Sourcing the best Welding Cables

We hope that this welding cable guide explains the basic of what these cables are made of, and how to determine the right welding cable size for your application. We’ve also explained how you can differentiate between welding cable vs battery cable and the finer points that might make one type a better choice over the other.

It’s now time for you to source the right type of cable for your application. Here, at ZW Cable, we bring a wealth of welding cable manufacturing to the table. Our vast range of products and low welding cable price makes us the supplier of choice for most welding projects.