PV Cable

- According to IEC, UL, and Standard

- Double Insulation

- Approved by SGS, BV, TUV

- In Stock

A Photovoltaic(PV) cable is a special cable for solar photovoltaic modules on the system, which has weather resistance, and UV resistance. And has a very long service life

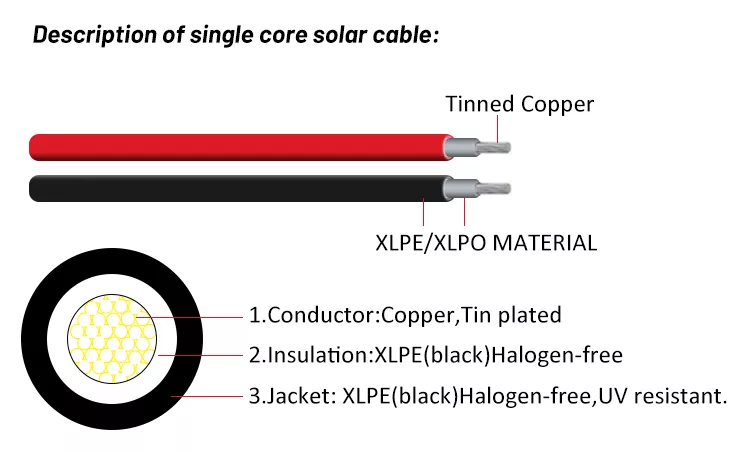

Conductor: Tinned Copper

Insulation: XLPO

Outer Sheath: XLPO

Color of outer sheath: Red, Black

Voltage: 0.6/1KV

Cross section (mm2) | Conductor Construction | Outer (mm) | Resistance Max. | Current Capacity |

1*1.5 | 30/0.25 | 4.90 | 13.30 | 30 |

1*2.5 | 50/0.25 | 5.45 | 7.89 | 41 |

1*4 | 56/0.3 | 6.10 | 4.75 | 50 |

1*6 | 84/0.3 | 7.20 | 3.39 | 70 |

1*10 | 142/0.3 | 9.00 | 1.95 | 98 |

1*16 | 228/0.3 | 10.20 | 1.24 | 132 |

1*25 | 361/0.3 | 12.00 | 0.795 | 176 |

1*35 | 525/0.3 | 13.8 | 0.565 | 218 |

1*50 | 720/0.3 | 14.8 | 0.393 | 280 |

Table of Contents

PV Cable: 6 Outstanding Attributes To Consider

The PV cables are only suitable for interconnections in solar photovoltaic power systems. They are among the newest cables on the market in recent decades. PV wires are flexible and resistant to moisture, sunlight, and fire.

As a result, these cables perform well in high temperatures. Photovoltaic cables are significant in the solar panel’s lifetime. This is essential for encouraging renewable energy sources like solar systems.

Several PV cable manufacturers have come up with different types or designs of wire. This guide provides you with six crucial ideas you need to know before buying a PV cable.

1. What is a PV cable?

A PV cable is a single core cable that connects solar-electric energy system panels. Also, solar combiners and junction boxes use PV wire. A photovoltaic system cable exists in two primary types: USE-2 and PV-labeled.

A photovoltaic cable’s principal role is to link solar junction boxes to solar combiners. These solar cables are flexible and meet the quality standards for outdoor usage. It means they must have waterproof and UV-resistant jacket insulation. Besides, it has to withstand temperature variations due to solar exposure.

Leading Cable and Wire Manufacturer-ZW Page Solar Cable & Wire According to TUV Tinned Copper,

The PV cable consists of copper with a moisture-resistant coating. Covering is suitable for moist environments. Notably, the insulation thickness varies depending on the PV cable size.

Solar cable manufacturers use 4mm solar wire for wiring and connecting components. This cable is ideal for outdoor use.

2. How can I choose a regular solar PV cable through the insulation?

Thickness

It is worth noting that thickness of the insulating layer matters. Inadequate thickness, less than the standard poses a risk of failure during usage.

Thicker insulation provides resistance against high temperatures and intense sunlight. This why solar PV wire does not deteriorates on a hot roof.

Check whether the level of cross-linking is inadequate.

Electrical performance is low when there is inadequate cross-linking and poor heat resistance. It also decreases with the inability to operate within the permissible range of temperatures. The cable in question has degraded electrical performance.

For instance, XLPO solar cable has excellent insulation. It can withstand high voltage and harmful substances. A double XLPO insulation layer is essential in a twin core solar cable. Twin solar cable helps in linking the inside and outside of a photovoltaic system.

Surface scratches

During shipping or installation, cables may get scratched by foreign objects. Be careful to inspect them before use.

You should check whether there is enough insulation. Also, check the service life of standard wires. You should also check if the connector of the solar cable is in place.

The insulating material of the conductor cable

PV cable conductor is made of tinned copper. Its primary use is outdoor applications, and the insulation makes it serve a long-term purpose. Even though the solar wire conductor is oxidable, it does not turn black easily.

Also, the insulation consists of a double-layer XLPO. This provides high-temperature resistance, cold resistance, and oil resistance. Additionally, it protects against acid and alkali salt, and UV. The insulation also acts as a flame retardant and protects the environment.

Thus, the photovoltaic power cable is suitable for use in severe environmental climate use. This earns the cable a service life of 25 years or more.

3. Why do we usually use a 4mm PV cable?

The 4mm solar panel cable consists of copper or aluminum solar wire. These two metals are the most conductive. Thus, wires can transmit electricity through them.

Electricity generated by solar panels needs a 4mm solar panel wire. It is usually to pass electricity to the home’s appliances.

The best practice for PV installations is using AC cables with a copper core. You must pay close attention to the transition technique. The wires might trigger a catastrophic failure if the procedure is incorrect.

Aluminum 1500 PV cable is suitable for both underground and outdoor applications. Connecting string boxes to solar inverters is ideal for this wire.

A 4mm PV wire is suitable for outdoor wiring. It provides excellent insulation and strong conductivity. Because of its high resistance to heat, it offers a solution in many situations.

Like a 10 awg solar cable, a 4mm PV cable is suitable for internal connections and solar panel installation. Unlike the PV cable 6mm, it is often utilized inside or underground.

The 4mm2 solar pv cable keeps your home and its occupants safe from harm. 4mm PV cable uses flame retardant and halogen-free insulators and compounds. This component makes it more resistant to UV light.

The 4mm wire can handle high temperatures without melting. They are also weatherproof, so you can put them wherever you want. They resist heat as high as 90 degrees and cold as -40 degrees. Maintenance costs are usually low.

Both the 4mm and 6 mm PV cables can tolerate high temperatures. Their installation can be outside or indoors. To make the most of any increase in load, a solar panel or photovoltaic system has a larger load capacity. A 6mm installation is your best bet if you want to maximize security and performance.

4. PV Cable vs USE-2 Wire

- PV cable withstands 90°C in wet and 150°C in dry conditions. Solar cable manufacturers design it for connecting PV modules.

But USE-2 wire can only withstand 90°C in dry or wet situations. Underground installations of USE-2 wire are frequent. Its users prefer it for linking service equipment terminals.

- Both PV cable and USE-2 wire have a 600V UL rating option. But PV cable can rate up to 1000V or 2000V if necessary.

- PV cable and USE-2 wire are suitable for grounded PV arrays. But, only PV wire is ideal for ungrounded arrays.

- PV cables are more robust due to their thicker insulation. But USE-2 wire has thinner insulation and is thus unsuitable for protection.

- USE-2 consists of either stranded or solid conductors. It is the best fit for settings that don’t need much mobility. PV cable is only ever suitable for solar panels. It eases bending without breaking.

- USE-2 wire goes down to 14 AWG, whereas PV cable may go down to 18 AWG.

- Unlike USE-2 wire, which has to pass a few misuse tests, PV cable must pass a flame test. It is also stringent UV resistance testing. A flame test is unnecessary for USE-2 since its uses involve areas where fires might occur. USE-2 is also exempt from having to be as resistant to sunlight.

5. Is it better to choose a twin-core or single-core photovoltaic cable?

A single-core solar cable has one conductor in an insulating layer. But a twin-core solar cable has two conductors in an insulating layer. Each of these categories has benefits and downsides. For example, a single-core cable is perfect when there is a solid, complete safety plan.

The twin-core photovoltaic cable current is more significant than that o the single-core photovoltaic cable. It is only when they have the same cross-sectional area. So, choosing a twin-core photovoltaic cable would be better. But it also depends on the purpose for which each would be an excellent solution.

A single-core photovoltaic cable has two ends that are immediately grounded. These ends contribute to an electrical loss. Additionally, the solar pv wire metal shielding layer wastes electrical energy. For this reason, the twin-core photovoltaic cable may be a better option.

A single-core photovoltaic solar cable is less costly than a twin-core photovoltaic cable. It is only when they have the same cross-sectional area. Thus, depending on your budget, you may choose either of them.

From an installation standpoint, a single-core wire seems rigid. But a twin-core wire is pliable and simple to wire. It now depends on the requirements that may make you decide on one to choose

6. Which supplier can produce high-quality PV cables?

PV wire manufacturers from China can produce high-quality PV cables. A reliable PV cable supplier is necessary to get these excellent PV cables. Companies like MC4 Solar Connector Solar Cable Manufacturer make high-quality mc4 cable.

Premier suppliers of solar cables insist on nothing less than perfection. Top solar PV cable manufacturers follow all international standards. As a result, they provide the highest possible quality and reliability.

The top solar cables they produce are in demand all across the globe. It is a guarantee that their items will meet your expectations.

You can also get PV dc cable from these manufacturers. For instance, it is common practice to use PV dc cables in a solar PV system. It helps in connecting the solar panels to the inverter or controller box. These cables can last for over 25 years under the sun’s rays.

PV cable prices may vary with the manufacturers and suppliers. Thus, ZW Cable would help if you make a comparison before settling on one.

7. Conclusion

PV cable has more robust insulation that can withstand various challenging situations. PV cable insulation involves XLPE, which provides good resistance to UV radiation. It also protects against weather and severe temperatures. For this reason, it has a wide application that includes the solar panel’s lifetime, which may last up to 25–30 years.

Some PV wire manufacturers may provide warrants over this period. Photovoltaic cable is available at various voltages. There are many designs of PV cables; thus, you need to contact your supplier on what may best suit your needs.