- Leading Cable and Wire Manufacturer-ZW

- Building Wire

Building Wire

- According to IEC and GB

- Class 1, 2, 6 Copper Structure

- Approved by IEC, GB, CE

- Nominal Voltage: 450/750V

- Large Stock Cable

The building wire cable is in charge of supplying electricity to the entire structure. Its appliances and devices are also included. All of our building wire types have been tested extensively to assure their long-term durability and dependability.

| Nominal section(mm2) | No./dia. of core(mm) | Average dia.(mm) | Reference weight(kg/km) | Conductor resistance at 20℃(Ω/km) |

|---|---|---|---|---|

| 1.5 | 30/0.25 | 3.5 | 20.6 | 12.1 |

| 2.5 | 49/0.25 | 4.2 | 33 | 7.41 |

| 4.0 | 56/0.30 | 4.8 | 48 | 4.61 |

| 6.0 | 84/0.30 | 5.6 | 68 | 3.08 |

| 10.0 | 84/0.40 | 7.6 | 115 | 1.83 |

| 16.0 | 126/0.40 | 8.8 | 176 | 1.15 |

| 25.0 | 196/0.40 | 11 | 272 | 0.727 |

Conductor: Class 1 (Solid), Class 2(7 Strands) , Class 6 ( Multi Strands)

Insulation: PVC

Working Temperature:-15°C + 70°C

6 Best Tips of Selecting Best Building Wire

Introduction

Almost every commercial, industrial, and residential structure is built with building wire and cable. The building cables transport electrical current to all power applications in a system or home. It would help if you incorporated some of the most significant building wires that can withstand the test of time.

Because you want to achieve your aim, the correct building wires and cables are crucial. Choose intelligently to have a dependable, sequential process that can readily react to unforeseen increases in performance needs. Some several cables and wires are only used during the construction phase of any infrastructure project.

We are the best building wire supplier in the market.

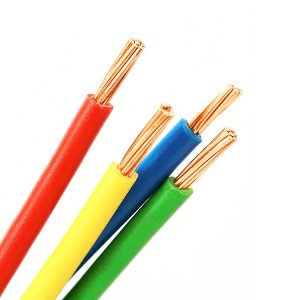

Figure 1: Building wires

1. What is building wire?

The building wire cable is in charge of supplying electricity to the entire structure. Its appliances and devices are also included. All of our building wire types have been tested extensively to assure their long-term durability and dependability.

You will obtain the most significant construction cable from us.

2. What Type of Wire Is Used in A Commercial Building?

Considering your goal is to have a stable, continuous system that can readily react to unexpected demands for higher performance, the proper wires and cables are essential.

THHN building wire is a nylon-coated thermoplastic wire that is heat resistant. For electrical wire and cable, it is constructed with specified insulation material. It also has a specific temperature rating and usage condition.

THHN wire is quite common for low-cost wire building purposes. It is used to wire machine tools, control circuits, and some appliances. The building wire is available with stranded or solid conductors.

It is made of copper or aluminum and is insulated with PVC and a nylon jacket. 10 thhn wire and 12 thhn wire are both nylon coated and has a higher cable strength.

Thermoplastic Heat and Water-resistant Wire is abbreviated as THW. The THW electrical wire is intended for usage in dry environments with temperatures up to 750 degrees Fahrenheit. Solid and stranded THW construction wire is available. Polyvinyl Chloride is used to insulate the conductor, made of soft galvanized copper (PVC).

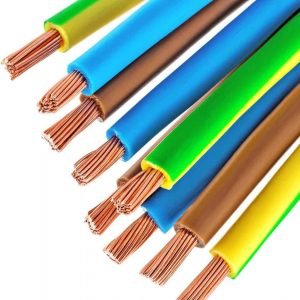

Figure 2. Pvc wire

We provide a variety of PVC Insulated Building wires and cables to our valued customers. These wires are ideal for power pass applications because they are highly resistant to chemicals and temperature changes. We provide 10mm building wre16mm building wire, 25mm building wire. The offered insulated wires are available to meet our client’s needs.

You can buy building wire that is fire resistant from our company. The refractory layer of mica materials in the fire-resistant type of building wire makes it heat-resistant. It ensures that the cable works effectively in the case of a fire. Many customers are keen to secure fire-resistant cables because they are simple to install.

- Flame retardant wire

We have flame-retardant building wire for sale. Flame retardants are chemicals that delay or stop a fire from spreading, providing you crucial time to flee. To boost the temperature at which a substance ignites, flame retardants are utilized in construction materials. It also reduces the rate at which things burn and prevents the spread of flames.

3. What is building wire made of?

In the production of our building wire cable, we prefer to use copper.

The tensile strength of copper building wire is greater than that of aluminum construction wire. It has a tensile strength that is around 40% higher than aluminum. It also has a higher wiring tensile strength than aluminum wiring, making it harder to break.

Copper cabling has a high strength and stiffness, which makes it resistant to breakage and other sorts of physical injury. Copper wire is also less thermally conductive than aluminum alloy. It does not stretch as much as aluminum wiring when heat is applied. When compared to other metals, copper is also quite affordable. Gold is a superb electrical conductor but is more expensive than copper, thus costly. Copper’s ductile qualities enable it to bend and flex. Heat resistance is a feature of a copper building electrical wire.

4. Building Cable Wire sizes

1.5mm, 2.5mm, 4mm, and 6mm Copper Core Electrical Wire PVC Covered varieties of building wire are available for IEC. They’re employed as field line installation, hanging cable, and drawing cable. The physical size and current carrying capacity of a wire are referred to as wire gauge.

The resistance and weight per unit length of the wire are also determined by the gauge rank. In AWG measurements, the conductor’s insulating is not considered. The smaller the conductor, the higher the AWG number.

For UL, our customers can choose from our company’s AWG 10, 12, 14, and 16 house cables.

5. What is the Conductor Resistance of Buling Cable?

The conductivity of a thin wire is greater than that of a thick wire. This is because a tiny wire can only transport little current because it contains low electrons. Resistance and the cross-sectional area of a wire are inversely proportional.

The tiny wire has a higher electrical resistance than the thick wire. Despite this fact, it conducts electricity. The electrical resistance of thicker wires is dramatically lower. Electrical resistance is much lower with thicker wires. The resistance of a thin wire is higher than that of a thicker wire.

It is more difficult for an electric current to flow via a thin wire. Resistance is also increased by using a longer wire. The conductor’s resistance is proportional to its length and inversely proportional to its bridge area.

The resistance increases when the length is increased. Insulators have an extremely high resistance to electrical current, whereas conductors have meager resistance. When dealing with actual electrical circuits, these two aspects become highly crucial.

The thickness of insulating material is essential in determining its breakdown voltage, also known as “dielectric strength.” Insulating materials generally have atoms with tightly bound electrons, preventing electron flow. However, at high enough voltages, electrons are freed from the atoms of insulating materials.

6. How to wire a building with electricity?

Household wires are color-coded, with white being the neutral wire. Hotwires are black/red. They transport electricity from the panel to a gadget. The bare/green color code indicates ground wires. When there is a ground fault, a ground wire is used.

Process of wiring a building:

- Turn off the electricity.

Request that the power company turns off the power to your home. Turn off power wire from meters in your house.

- Mount Electrical Panel

At the location where the power company’s wires enter your property, install an electrical panel. With a hammer and screwdriver, make holes in the panel for the power leads and slip-lock pliers, screw knock-out clamps into the holes. Feed the cables through the clamps and tighten them.

- Establish a connection

Pound a metal ground rod into the surface and use an 8-gauge copper wire to connect the panel to the rod. Join one end of the rod to the service panel’s ground bus. A ground clamp secures the other end of the rod.

- Install a circuit breaker.

A circuit breaker connects each electrical circuit in the home to the panel. Feed each circuit cable via a knock-out hole in the panel to which a clamp has been affixed. Connect each cable’s white wire to the silver bus. The black wire is connected to a breaker, and the ground wire is connected to the ground bus. Each breaker is put in an open slot on the brass bus. Connect the red and black wires to separate breakers on a matched set for 240-volt circuits.

- Make adjustments to the circuit breaker

Drill holes in the floor and walls to run the cables from the panel throughout the hose. To avoid overloading the breaker, plan the circuits to use the least amount of cable possible. Fix the cables to the floor joists, roof rafters, and wall studs using staples tightly. Drill holes in wall studs at least 1 inch apart from either face to avoid piercing them with drywall screws.

- Install the electrical box

Each outlet, switch, or light fixture should get its electrical box. If the wall is already finished, you can fasten the boxes to studs or rafters. A rebuilding box that attaches directly to the drywall can also be used. Leaving twisted and capped wires exposed is dangerous and against the law.

- Choose the correct cable size

The cable should be sized according to the circuit breaker. For 10- and 15-amp breakers, a 14-gauge cable will suffice, but for 20-amp breakers, the thicker, 12-gauge wire is required. For any 240-volt application that requires a 30-amp breaker, use a 10-gauge, four-strand wire. If the appliance requires a 50-amp breaker, use an 8-gauge wire. Remember that each 240-volt appliance is connected to its circuit.