MV Cable

- According to IEC and BS Standard

- PVC Insulation

- Large stock cables with different sizes

Mv cable is a medium voltage cable with a voltage rating from 5kv to 36kv. The conductor of the cable is usually copper or aluminium, but most people choose the copper conductor because of the long service life of the cable.

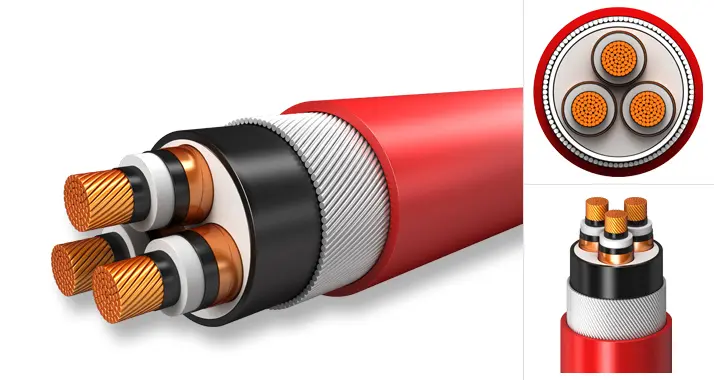

Conductor Material: Copper

Conductor Screen: Semi-Conductor Polymer

Insulation: XLPE

Insulation Screen: Semi-Conductor Polymer

Metal Screen: Copper tape

Insulation Sheath: PVC

MV Cable: A Perfect Combination of Strength and Reliability

In the world of technology, we are always looking for new ways to make our products stronger, more efficient, and easier to use. In the case of MV cable, we have found a perfect combination of strength and flexibility. With this type of cable, we can easily connect two medium voltage devices without worrying about the strength or flexibility of the connection.

A medium voltage power cable is an electrical cable that transmits electric power at a medium voltage (MV) level. It is also known as MV cable. While most MV cable is manufactured with copper or aluminum conductors, some particular types are also made with other materials like carbon. MV wire is made from a specific kind of insulated wire designed to withstand high voltages and currents.

What is MV Cable?

International Electrotechnical Commission (IEC) has defined medium voltage power cables as “cables having conductor cross-sections up to and including 1000 mm2, insulated for voltages from 5kV up to 36 kV, intended to be used at rated voltages in power distribution networks and industrial installations.”

Various cross-sectional areas and insulation thicknesses are used for MV cable to accommodate different voltage levels. The most common type of MV cable is the 11kV cable. 15 kV cable is also a popular type of cable MV. It is often used in underground power distribution networks.

Mv armoured cable is another popular type of mv cable. It is used in various applications where durability and strength are required, such as in underground or exposed environments. In contrast, Mv underground cable is designed for direct burial applications. As the name suggests, it is specifically designed to withstand the harsh conditions found underground.

What is the type MV Cable?

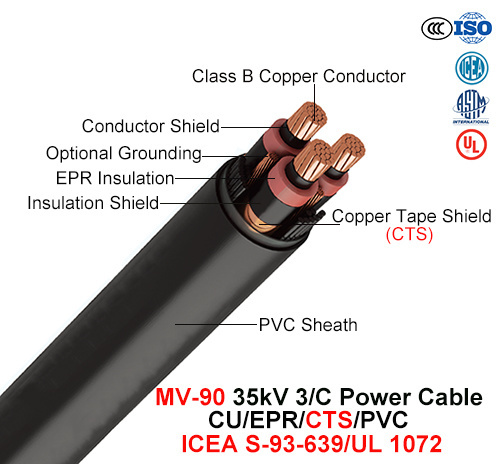

Single-conductor or multi-conductor cable rated for 2001 volts up to 35,000 volts is referred to as Type MV cables. An MV-90 or an MV-105 is used to designate the maximum conductor temperature in degrees Celsius (ºC), depending on the type of single-or multiple-conductor cable.

Insulation levels for type mv cable typically include 100%, 133%, and 173%. The voltage range for type MV cables includes:

- 5kV

- 15 kV

- 25kV

- 36kV

Type MV Cable With Concentric Stranding

The concentric stranding of aluminum or copper conductors, semi-conductive layer, insulation, and an overall sheath make up type MV cable. The construction of such cables is based on the need for a conductor that can easily be applied in congested areas. This conductor must also be able to withstand high temperatures and voltage drops.

According to the ICEA Standard S-96-658, type MV 90 cables are used in industrial plants, utility substations, generating stations, and switchyards where limited space and high temperatures are typical. The maximum conductor temperature of an MV 90 cable is 90ºC.

On the other hand, type MV-105 cables are used where space is not an issue and high temperatures are not as typical. The maximum conductor temperature of an MV 105 cable is 105ºC.

What are MV 90 cable and MV 105 cable?

The MV 90 copper cable is a power cable that can be used for electrical circuits up to 15,000 volts when installed in the open air, ductwork, or conduit. It’s commonly utilized in refineries, steel mills, and other heavy industrial applications where severe physical or mechanical hazards are present.

MV 105 cable is a single conductor mv power cable used for secondary distribution circuits. MV 105 used in applications has voltage ratings of up to 15kv buried directly in the ground or ductwork. Mv 105 15kv cable is commonly used in residential and commercial construction where long lengths are necessary to reach the main electrical panel.

How do I choose MV Cable?

Choosing the suitable MV cable is vital to ensure the long-term success of your project. To select a medium voltage wire, you must first understand the different considerations involved in the selection process. This guide will introduce you to the different types of MV cable and their applications to decide which product is suitable for your needs.

1. During unexpected or emergency circumstances, medium voltage cables are frequently required:

Workers dealing with an unexpected and urgent need may find it challenging to install sturdy cables. Mv cables are available with a high degree of flexibility and can be installed quickly. To connect two points to provide an alternate power source, for example. Other situations where medium voltage cables may be needed include new construction projects or upgrades and expansions to existing electrical systems. For these reasons, it’s essential to understand the different types of medium voltage cables available and their capabilities.

2. If you’re working with medium-voltage cables, you’ll need to make sure they’re cut correctly:

When cutting medium-voltage cables, it’s essential to consider a few factors. The first is the type of cable you’re working with. For example, if you’re dealing with a solid core cable, you’ll need to use a different cutting method than working with a stranded core cable. It’s also important to consider the insulation surrounding the cable. The wrong type of cut can damage the insulation, leading to electrical problems down the line.

Finally, you’ll need to consider the size of the cable you’re working with. A smaller diameter cable will require a different cutting method than a larger diameter cable. A perfect mv cable size cut is essential to making a safe and secure connection.

3. The Connections on MV cables should be exceptionally well-engineered:

MV cables are designed to handle high electrical loads, so it’s crucial that the connections are well-engineered and can withstand the stress of heavy use. The best way to ensure that the connections are up to the task is to work with a reputable MV cable manufacturer. A good manufacturer will use only the highest quality materials and employ experience. Mv cable specifications should be strictly adhered to achieve the best results.

4. When an unexpected outage necessitates immediate action, you can’t wait for materials:

If you find yourself in a situation where you need medium voltage cables urgently, you can’t afford to wait for delivery. That’s why it’s crucial to work with a supplier who has a large inventory of MV cable in stock and can ship it to you quickly. In addition, it’s essential to choose a supplier who has experience dealing with urgent requests. They should be able to provide you with guidance and support so that you can get your project up and running as quickly as possible.

5. Consider your options for deployment and enlist the help of a partner:

There are a few different options for deploying medium voltage cables. One is to install them above ground, which can be done using either supports or conduits. If you’re installing the cables underground, you’ll need to trench and lay them in conduit. In either case, it’s essential to enlist the help of a partner who has experience with MV cable installation. This will ensure that the job is done correctly and that the cables are laid in the correct configuration.

Why are MV cables shielded?

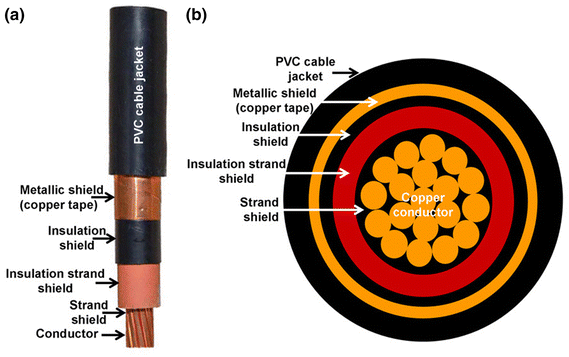

MV cables are shielded to protect against electromagnetic interference (EMI). EMI can be caused by electrical equipment, such as motors and generators, or by outside sources, such as power lines. Shielding helps to prevent EMI from affecting the performance of the MV cable.

The insulation and conductor shield block the external electric field while conducting the core. The insulating electric field, 6kV and above medium and high voltage cable usually have a conductor shield and insulation shield, whereas low voltage cables do not.

A semi-conductive shield and a metal shield together make a shield layer. A semi-conductive shield is usually carbon black and protects against electrical impulses and static charges. On the other hand, a metal shield helps to block electromagnetic fields.

The semi-conductive shield is a highly conductive yet very low resistance, thin semi-conductor material. The innermost layer of the semi-conductive shield is in contact with the conductor, while the outermost layer is in contact with the insulation. This creates a capacitive coupling between the conductor and the semi-conductive shield, which helps to protect against electrical impulses.

The metal shield is usually made of copper or copper tape. The metal shield is in contact with the semi-conductive shield. This creates a Faraday cage around the conductor, which helps to shield electromagnetic fields.

Conclusion

To sum it up, an MV cable is the best choice for high voltage and power applications instead of a high voltage power wire. It is a perfect combination of strength and flexibility. The cable is also resistant to extreme temperatures, weather, and chemicals. Thanks to its superior properties, an MV cable can last for many years without any problems. We being reliable MV cable manufacturers, always focus on customer satisfaction. To know more, please visit ZW Cable.