- Leading Cable and Wire Manufacturer-ZW

- Screened Cable

Screened Cable

- According to IEC and GB Standard

- PVC & LSZH Cable

- Approved by GB, IEC, RoHS, SGS, BV

- Rated voltage 450/750V

Screen Cable is a transmission line that uses a metal mesh braid to wrap the signal line, and the braid is usually red copper or tinned copper. The shield layer of a shielded wire needs to be grounded, and foreign interference signals can be directed to the earth by this layer. The braided cable is a wire with a metal braided casing specifically used to reduce the impact of external electromagnetic fields on power or communication lines.

Conductor: Copper or Tinned Copper

Insulation: PVC

Shield layer: Tinned copper or Copper Wire

Sheath: PVC

Related Voltage:450V/750V

Introduction

The electric cable is a crucial piece of equipment in the modern world. It plays a vital role in data transmission or electricity over long distances. For this reason, over the years, continuous innovation has led to the invention of the screened cables.

Like other modern inventions in the cable industry, the screened cable has unique capabilities. Its safety and efficient performance have made it the preferred choice in many electrical installations. It is also widely used in various structures and electrical devices.

1. What Is A Screened Cable?

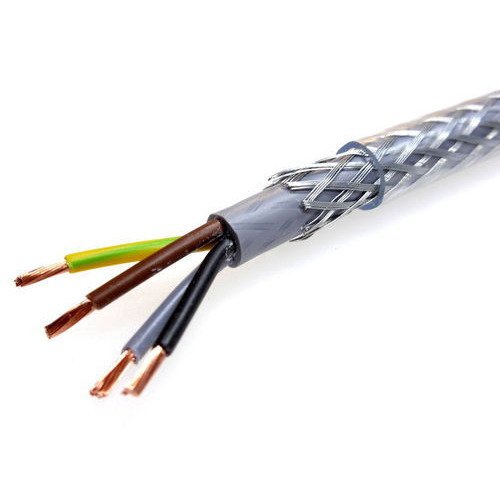

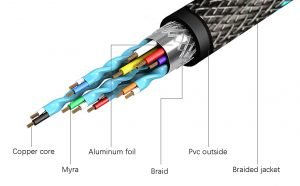

Figure 1: Screened Cable

The Screened cable is a uniquely designed electric wire comprising of one or more conductors under insulation, surrounded in a regular conductive layer. This layer is mainly composed of braided copper or aluminum strands. A conducting polymer or a non-braided copper tape can also be used.

Normally, this layer is covered with a plastic jacket. Screen cables are also referred to as shielded cables. They are used to minimize the conjoining of inner cables in the installation spaces. These cables are extremely efficient in protecting the data from electromagnetic interference while being sent over the wires.

2. What Is the Difference Between a Screened and Unscreened Cable?

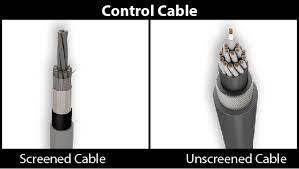

During installation at your home or workplace, you are required to decide what type of cable will be used. Your decision is determined by the level of safety and efficiency you wish to achieve. The main choices you have are between screened and unscreened cables. Here are the main differences between the two cables.

Screen cables usually include the same parts as unscreened cables, but they emit far less electromagnetic radiation, which might interfere with signals in neighboring cables owing to the screen’s capacity to absorb and deflect them.

On the other side, unscreened cables are simple to make and inexpensive since the sheath/shield is generally comprised of pure aluminum or copper, lowering the wire’s cost. Only the twisted pairs with the primary outer sheath/insulation are present in unshielded wires.

Figure 2 Screened cable and unscreened cable

3. What Are the Types of Screened Cables?

There are various types of screened cables available in the market. They include shielded cables and unshielded cables as follows.

Shielded screened cables

- Foil shielded screen cables– Foil shielding is made of a thin sheet of aluminum or copper. To increase the cable’s strength, this “foil” is generally attached to a polyester carrier. This form of shielded cable, often called “tape” shielding, provides 100 % protection for the conducting wire it is rolled around.

Typically, 4 core screen cable 0.75mm, 6 core screen cable, 4 core screen cable 0.5mm, 3 core screened cable, 8 core screened alarm cable, 4 core screened control cable, single core screen cable, and two core screen cable are foil shielded to prevent conductor wire from mechanical damage.

- Spiral shielded screen cables– They involve a low-cost spiraling shield constructed of copper strands flowing parallel to each other. Because the cable’s ends do not need to be untangled, it may be assembled fast. It’s simpler to stretch since the strands are spiraled.

Many kinds of cables such as copper wire screen cables, 4 pair screened cable, twin-core screen cable, two core screened cable, and armored screened cable.

- Combination shielded screen cables – They consist of more than one insulator shield. They may include 4 pair screened cable, single core screen cable, two core screened cable, 6 core screened cable, and 4 core screened cable 0.75mm.

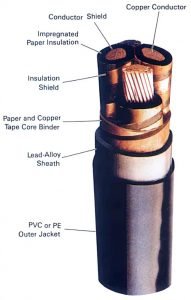

Figure 3: Example of combination shielded screened cables

- Metallic braid shielded screen cables– The shields are generally made of copper strands that are bare, tinned, or silver plated. Physical protection can be provided by steel and other metals. They are woven over a conductor or conductors similar to how a textile braid is braided over a conductor or conductors. For instance, copper wire screen cables may be insulated using metallic braid shields.

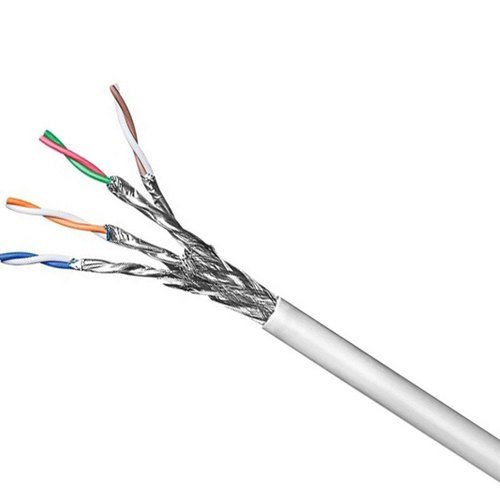

4. What Is a Screened Shielded Twisted Pair Cable?

A screened twisted pair cable is a wiring type where the two conductors in a single circuit are conjoined. This is mainly done to improve its electromagnetic compatibility and reduce interference from radio frequency.

These cables are commonly referred to as a shielded twisted pair, foiled twisted pair, or a screened twisted pair. The cables also reduce noise.

This happens when the interference/noise created by one wire is successfully neutralized by the interference/noise produced by the other wire by twisting wires that carry an equal and opposite amount of current through them.

In the data transfer industry, the screened shielded twisted pair cable is capable of supporting higher transmission rates over long distances.

Figure 4: Typical screened shielded twisted pair cables

5. What Is the Current Market Price of a Screen Cable?

The prices of screen cables range between $1 to 5$. However, the cost of the cables varies with the nature or form in which they exist.

For example, a single-core screen cable may be less expensive than a twin-core screen cable or any other such as 3 core screened cable, 4 core screen cable 0.5mm, 4 core screened control cable, 6 core screened cable, and 8 core screened alarm cable.

6. What Are the Uses of a Screen Power Cable?

The screened power cables are utilized in various settings. The most common use of the cables includes connecting a computer, display monitor, printer, or HDD enclosure.

The screen power cable is designed to fit into a 3-pin shrouded power connection used on many monitors, scanners, hard disk enclosures, printers, and other devices. These cables exist in several lengths appropriate for most applications.

Besides, manufacturers of security systems use screened power cables as they offer protection from radio and power frequency interference. This greatly lowers the occurrence of false alarms.

In communication, shielded cables protect the information from the effects of electromagnetic radiation. This is very common in offices and data centers where electrical equipment and computers are in high use.

Other than mitigating the loss of data while being transferred, screened cables also lower electrical noises.

Figure 5:Copper Screen Power Cable

Figure 6 Tinned Copper Screen Power Cable

Screened Cable Summary

The screened cable comprises of at least one insulated conductor. The purpose of the screen component is to keep the signal from escaping the cable while also preventing external electrical noise and interference from influencing the signal it’s carrying.

The screened cable exists in two primary types as shielded and unshielded. The cost of the screened cable ranges between $1 and $5 depending on the kind and design of the cable. The main uses of the screen cable are connecting devices.

For instance, a screen power cable is used to connect computers, printers, display monitors, or HDD enclosures.