- Leading Cable and Wire Manufacturer-ZW

- Marine Wire

Marine Wire

- According to IEC, GB, BS Standard

- Flame Retardant & LSZH Cable

- Approved by ISO, CE, UL

- Accept Lower MOQ

Marine Wire: A Perfect Option for Your Underwater Networking Needs

Marine wire is the best option available when it comes to electrical wiring on board a vessel. Marine cable is designed specifically for saltwater environments and can withstand the harsh conditions found aboard a boat. This type of cable is also known as boat wire or marine grade wire.

Marine wire is made from tinned copper marine wire, then covered with PVC insulation. The tinned cable prevents corrosion, a common issue with standard copper wiring. Tinned marine cable is also available in different gauges, which refers to the thickness of the wire. In this guide, we will discuss the different types of marine cable available and when and where to use them.

What is Marine Wire?

Marine wire is a metallic wire designed to withstand water and corrosion. The vast majority of marine cables on the market are constructed of tinned copper and PVC insulation. Marine cables are typically used for electrical power distribution, communication, basic circuit wiring, and propulsion systems in boats and ships.

Marine wire cable is designed to be used in salt water and other harsh environments. The insulation on marine cables is often thicker than standard electrical wire to protect against abrasion and ultraviolet (UV) rays. It is also known as boat wire, marine grade wire, or marine tinned wire.

The marine electrical wire must be tinned to ensure long-term performance in salt water. The tinning process adds a thin layer of solder to the copper conductor. This creates a barrier between the metal and the environment, preventing corrosion.

What makes marine wire different?

A marine wire is thicker, longer, and heavier than a vehicle cable of the same size. As a result, 6 AWG marine cable has more copper than 6 AWG automotive extension cord. The higher the copper content, the greater the current carrying capacity of the cable. The PVC jacket of the marine cable is also durable and robust.

The most critical factor in a marine cable and wire is the thickness of its conductor. A thin conductor will heat up quickly, potentially causing a fire. A thicker conductor can carry more current without heating up, making it safer.

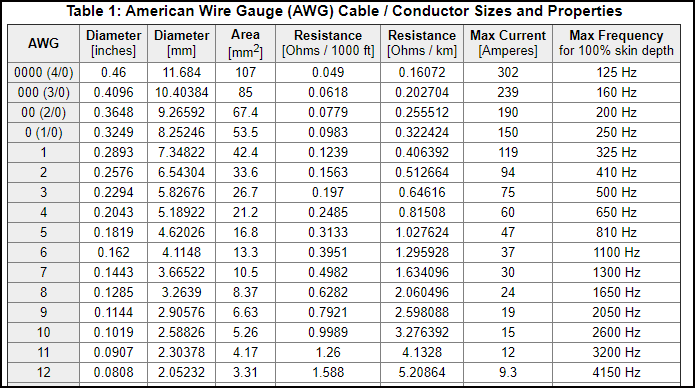

When discussing the marine wire size chart, you must first understand the gauge system. The lower the number, the thicker the wire. So, a 10 gauge marine wire is thicker than a 12 gauge marine wire.

The American Wire Gauge (AWG) system is used to measure the diameter of the marine wire. In this system, the thickness of the marine wire increases as the AWG number decreases. 8 gauge marine wire is often used in small boats to connect the batteries to switches and accessories.

A 2 gauge wire is the thickest marine wire size. It can carry up to 65 amps of current. A 6 gauge marine wire is the thinnest marine wire size. It can carry up to 20 amps of current.

A marine power cable is used to connect the battery to the engine. It is also used to connect the battery to accessories like lights and horns. The most common marine power cable sizes are 4 AWG, 6 AWG, and 8 AWG.

What gauge wire for marine battery?

When it comes to wiring your marine battery, the general rule is that bigger is always better. A thicker gauge wire will be able to carry more current without overheating, so if you’re unsure which size to go with, err on the side of a larger diameter wire.

4 gauge wire is the most popular size for marine battery wiring, with 6 and 8 gauge also being common choices. If you’re looking for the best marine wire for boats, it’s essential to choose one that’s specifically designed for marine applications.

Marine battery wire is designed to withstand the harsh marine environment, including exposure to salt water and UV rays. It’s also essential to choose a marine battery cable rated for the specific voltage of your boat’s electrical system.

For example, if you have a 12v marine wire system, you’ll need to use wire marine that’s rated for 12v.

If you’re not sure which marine battery wire is best for your boat, it’s always a good idea to consult with a professional. At ZW Cable, we offer a wide selection of marine battery wires and other marine electrical cable to meet your specific needs.

Why use Marine Cable?

If you are wondering why you should use a marine cable instead of regular wire, the answer is simple. Marine wire is specifically designed to withstand harsh conditions, including exposure to salt water, sunlight, and extreme temperatures. This cable type is also usually made from Tinned Copper, which offers superior corrosion resistance.

From the salt water to the sun, your boat is exposed to pretty harsh conditions. That’s why it’s essential to use a cable marine instead of regular wire. The marine cable is necessary for vessels that spend time in the water. Not just the cable that goes to your boat stereo, but all of the wiring on your vessel should be marine grade to prevent corrosion and other damage.

In comparison to regular wire, marine wire has the following benefits:

- It is resistant to salt water, humidity, and other harsh weather conditions.

- It can withstand high temperatures and has a higher voltage rating.

- Marine cable is flexible and easy to work with.

Marine cable is used for a variety of applications, including:

Underwater applications:

Marine cables are used extensively in underwater applications such as off-shore oil drilling, deep-sea exploration, and other similar operations.

Submarine communications:

Submarine cables play a vital role in global communication systems. They transmit data and information across continents and oceans at high speeds.

Electrical power transmission:

Marine cables are also used for electrical power transmission from one place to another. These cables are highly efficient in carrying large amounts of electrical current over long distances.

Offshore wind farms:

Offshore wind farms are a growing source of renewable energy. Marine cables connect the offshore wind turbines to the onshore grid.

Aquaculture:

Marine cables are also used in aquaculture operations. They are used to connect the cages or pens where fish are raised to the shore.

Other applications:

Marine cables are also used in various other applications such as offshore moorings, wave energy farms, tidal energy farms, etc.

Where to buy marine wire?

As the weather gets warmer and the boating season approaches, many boat owners are getting their vessels ready for the water. If you’re one of them, you may be wondering where to buy marine wire.

ZW cable is one of the country’s leading marine wire manufacturers and suppliers. With over 10 years of experience in the industry, we can provide our customers with high-quality products at competitive prices. If you are looking for marine-grade wire, we have a wide selection of products.

Whether you need a single conductor or multi-conductor cable, we have the right product for your application. When finding the best marine wire manufacturers, ZW cable is your top choice!

Conclusion:

Marine wires are an essential part of the infrastructure of any maritime operation, and it is crucial to choose the right type of cable for the job. The above guide has provided an overview of the different kinds of marine cables available and their key features and benefits. ZW cable is a professional marine cable manufacturer and supplier; we can provide you with high-quality marine wires that encounter your needs. Contact us today to learn more about our products and services.