- Leading Cable and Wire Manufacturer-ZW

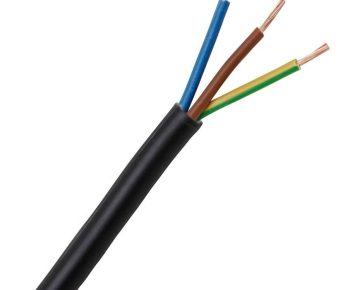

- rubber cable

rubber Cable

- According to IEC Standard

- Rubber

- Approved by CCC, CE, SGS

- Related Voltage 450/750V

Rubber cable is a variety of rubber or performance of thermosetting elastomer for insulation and sheathing based on wire and cable. The so-called thermosetting plastic elastomer is after a heating moulding curing, the shape of its internal molecular changes to stabilize the shape usually this process is called vulcanization or cross-linking. It was heated again to achieve a viscous flow state, the elastomer for processing and moulding. Rubber insulated cable is flexible and used in electrical equipment.

What are the rubber cable products?

Rubber cables include rubber-sheathed flexible cable, mining cable, rubber wire, welding cable, submersible cable.

Rubber flexible cable used in various outdoor and outdoor environments. Rubber coat cable has enough flexibility to move and bend. The weight of the cable is light. Overall diameter is small and easy to use. Rubber coated cable can withstand significant mechanical external forces. The sheath has high mechanical properties, good wear resistance and elasticity, and a certain degree of flexibility.

Flexible rubber cable is often affected by bending, torsion, friction and other mechanical forces in the use of move frequency which requires the cable to be soft and wear-resistant. The cable used outdoors to withstand the sunlight, so also require such cables have sunlight ageing resistance and oil resistance and moisture resistance.

Mining cable is used in large quantities in mines. The mines have many explosive and flammable substances such as gas, dust, electrical safety requirements. The mine is wet and may have corrosive substances.

H07rn-f rubber cable moves frequently and is often subject to bending, twisting, dragging, and smashing impact. The wires used in the open field can withstand daylight’s effects, so the requirements for mining cables are particularly stringent. The conductive core should be highly flexible, often using thin, stranded copper wire at a small pitch.

The insulation layer should have high electrical resistance and mechanical strength. The cable must be smooth, wear-resistant, impact-resistant, and can be frequently bent, and has good flame retardant properties. The cable sheath is much thicker than the rubber flex cable to increase the cable’s impact resistance and smash resistance.

Welding cable is characterized by low voltage, high current, moving frequently, often subject to twisting, bending, dragging and other effects, the use of the environment may have acid, alkali, oil, etc., so the welding machine cable requirements conductive core to be very soft, insulation to be flame retardant, sheath to have wear-resistant oil resistance, atmospheric ageing and other properties.

The submersible cable is mainly used for AC voltage 450/750V and below submersible motors or submersible pumps connected to the power supply, can also be used for oil pollution occasions.

Why use rubber for cable insulation?

Rubber cable has good stability at high temperatures and a low-temperature environment to maintain good electrical performance. Rubber cable can keep good electrical energy no matter in hot summer or cold winter. Rubber cables are mostly used as power cables. In the complex outdoor environment, rubber cables’ performance in acid and alkali resistance and corrosion resistance is essential. Rubber cable can play the maximum performance to reduce power loss has a good stretch, good wear resistance, while the service life is a more prolonged and more significant reduction in the coefficient of the occurrence of danger.

Is rubber cable waterproof?

Waterproof cable, which mainly refers to stopping water from entering the cable structure’s interior, is a structure and material with a waterproof function on the cable’s sheath. The waterproof cable is generally 3 cores. Usually, we say that the waterproof cable refers typically to the diving line, the pump cable. Water pump cable also belongs to a kind of flexible rubber cable. The insulation is rubber. Therefore rubber cables and pump cables can be used in water.

Rubber cable also has waterproof, but not professional waterproof, but wire and cable are different sense with waterproof. First of all, not all cables are waterproof. The laying environment determines the waterproof cable. In general, the waterproof cable includes the cable laid in the river or under the sea. Such cables generally have a waterproof insulation layer and are armoured.

What is the difference between silicone rubber cable and rubber cable?

Silicone rubber cable has better bending performance and low-temperature performance, not easy to damage and to crack. These properties are not generally high-temperature cables. Thus, silicone rubber cable has a wide range of applications and highlights the high-temperature cable.

Silicone rubber cable is suitable for AC rated voltage 0.6/1KV and below fixed laying with power transmission line with connecting cable, the product has the characteristics of heat-resistant radiation, cold, acid and alkali resistance.

The cable has a soft structure, convenient radiation, stable electrical performance under a high temperature (high cold) environment, outstanding anti-ageing performance and long service life. Silicone cable widely used in metallurgy, electric power, petrochemical, electronic and automobile manufacturing industries.

Rubber cable is widely used in various electrical equipment, such as daily appliances, electric machinery, electrical devices, and power cable appliances.

Rubber Cable Vs PVC Cable

PVC cable is the most common insulation material and the cheapest with a wide range of uses. The temperature range is from -10°C to 70°C. PVC is not as flexible as other types of wire. Rubber Cable is highly flexible and heat resistant, more suitable for extreme temperature environments from -30°C to 120°C, and soft to the touch. One disadvantage of rubber is that it is usually more expensive and attracts static electricity to be dirtier than other wires.

Natural rubber can be considered a hybrid of silicone and polyvinyl chloride because it has some advantages and disadvantages. It has better abrasion resistance than silicone but is not always as chemically resistant as PVC. It is better suited for outdoor and industrial environments.