- Leading Cable and Wire Manufacturer-ZW

- Teflon Wire

Teflon Wire

- According to UL Standard

- Teflon Insulation

- Approved by UL, RoHs, GB

- Different Colours

Teflon wire has excellent corrosion resistance, almost insoluble in any organic solvent, can resist oil, strong acid, strong alkali, strong oxidant, etc., and has excellent electrical insulation performance, high voltage resistance, low high-frequency loss, no moisture absorption, high insulation resistance. Teflon cable has excellent fire resistance, ageing resistance and long service life.

Conductor: Copper, Tinned, Nickel Plated Copper Wire

Insulation: Teflon

Voltage: 600V

What Is TEFLON WIRE and How Does It Work?

Cables and wires are the most common objects in our lives, but we can not underestimate the cables. If people’s life without these wires, our electricity becomes the biggest problem. And we are currently in contact with a variety of wire types. Teflon wire is one of them.

what is teflon wire?

Teflon coated wire is a kind of wire with fluoroplastic as the insulation layer, and this kind of wire is also called teflon cable. Since fluoroplastic is also a type of plastic, Teflon also has the title of “King of Plastics.” The Teflon insulated wire production process is relatively simple.

Many friends may be interested, here to briefly introduce its production process: the first step, the copper slag or copper-containing materials into the boiler, pumped into the very high-pressure oxygen so that the temperature reaches the boiling temperature of copper water.

The second step is to pour the copper into the mould, and after the mould is cooled by immersion, the temperature is then processed.

The third step is to remove the impurities in the forming module utilizing an electrolytic bath, and the copper plate is melted again.

The fourth step is to pull the cooled pure copper water into thicker copper strips, and then the copper strips are made into wires of suitable thickness and size.

Finally, a layer of Teflon insulation is added to the wire’s outer layer. PTFE wire is currently used in the electronics industry and can be used as a temperature compensation wire. Moreover, we usually use many home appliances, such as air conditioners, rice cookers, microwave ovens, electric kettles, and other internal cables, commonly used FEP wire and PFA Wire.

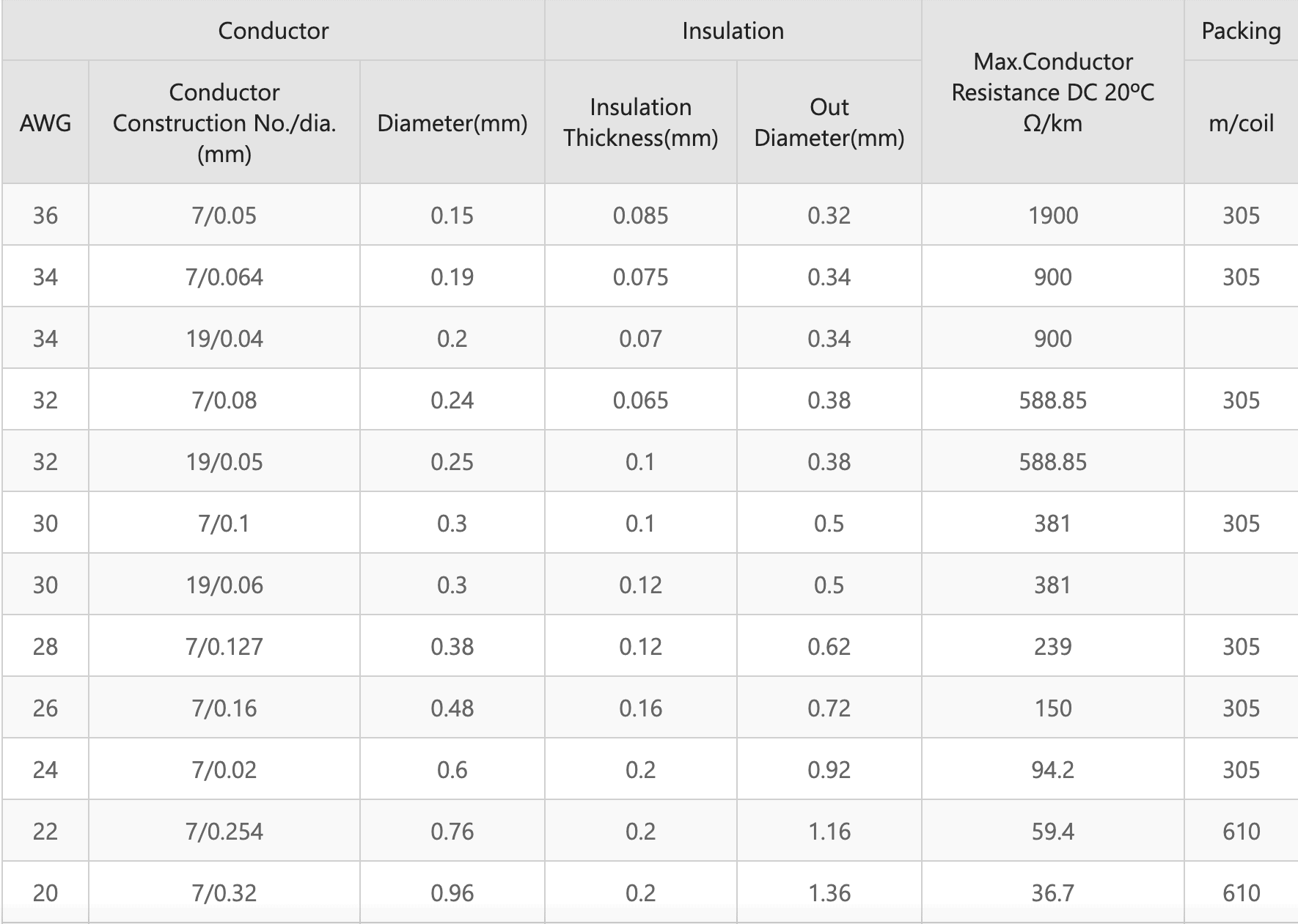

Teflon wire specification

Teflon is a fantastic material in people’s eyes. PTFE cable is made of Teflon material, which many people will also admire to the core. So, is this wire that good? Let’s see what advantages teflon cable has.

Non-stick Teflon does not produce bonding with any substance. PTFE wire belongs to the non-stick coating, and dust stains are tough to stick on Fluorine wire.

1, heat resistance and low-temperature resistance are excellent, can be used continuously between 240 ℃ ~ 260 ℃, and maintain the wire’s stability, will not melt; in a low-temperature environment.

2.Will not melt. In a low-temperature environment, teflon wire insulation will not become stiff and brittle.

3、 Insoluble in any organic solvent, including water, oil, and other substances that will deal with the wire in life. This also means that teflon coated copper wire also has the characteristic of not absorbing moisture.

4、Abrasion resistance Under the specified load, the teflon hook up wire is not only non-adhesive but also very wear-resistant; even under high load, it also has excellent wear resistance. Drugs and chemicals will not corrode

5 、Corrosion resistance, and in the case of firm acidity and alkalinity, it can also ensure that the parts are not damaged.

Where to buy teflon wire?

When choosing Teflon wires, many friends usually tend to choose inexpensive cables to compress the wires’ expenses. But in fact, the wire is about the family’s electrical safety. If the wire’s quality is not up to par, it may cause some electrical safety hazards.

First, see if the product can provide UL certification. Because the UL certification mark is the greatest embodiment of a safe creation, it is to prove its quality. Choose ZW Cable will be your best choice!

Second, look at the thickness of the insulation layer of the product.

Different types of wire, the thickness of the insulation layer is different. There is a range of values. And the thickness of the insulation layer of high-quality wire is relatively uniform, right on the core.

Third, look at the product core is in line with the regulations.

The regular wire is made after strict drawing, annealing, stranding, and other processes to make the core surface smooth, bright, and burr-free, challenging, and not easy to break.

Can Teflon wire use in water?

Plastic is waterproof, and as the king of plastics, Teflon has advantages in terms of water release. In the previous introduction, we also know that teflon copper wire is better in water resistance and corrosion resistance. So, is it true that Teflon wire used in water?

Teflon is a material that does not blend with other organic solvents, which include water. Therefore, it is impossible to put Teflon wire in water without contact. In other words, the fluoroplastics wire can go inside the water.

However, it is essential to note that even if the PTFE wire has good water resistance and can be run in water. But no one can guarantee when the wire will be ageing or damaged. If the wire is placed in the water for a long time, it may also cause safety hazards, such as leakage.

In short, if you do not have to put the wire in the water, the wire should be placed in a dry place as far as possible. If the wire installation environment really can not avoid the erosion of moisture, you can first put the wire in the wire tube and then the construction, so at least you can extend the wire’s service life.

Teflon wire vs PVC wire

We usually refer to wires that can conduct and transmit electricity collectively as electrical wires, but we underestimate electrical cables. Sometimes, even if two wires look similar on the outside, they may be completely different. Teflon wire and PVC wire, for example. So, what is the difference between these two types of wire?

First, the thickness of the insulation layer is different.

Teflon insulated copper wire is made of teflon insulation. The insulation is the thickness and PVC insulation is thicker.

Second, teflon material has a good flame retardant, with a lighter directly to burn, is not easy to ignite, while PVC material is straightforward to be ignited. Easy to be ignited. At this point, the two are very good to distinguish.

Third, the degree of preheating melting is different.

Pvc material resistance to high temperature is inferior, in a high-temperature environment, it is easy to be melted away, while the Teflon is difficult to hot melt, and heat resistance is excellent.

Fourth, the appearance of different feelings. From the point of view of the wire’s appearance, the brightness of the two is different. Pvc material will look duller, while Teflon brighter.

As a Teflon wire manufacturer, we can produce many gauge teflon wire such 18 awg teflon wire, 30 awg teflon wire, 20 awg teflon wire and 30 awg teflon. Our products are exported to Europe and the United States. We accept lower MOQ.