- Leading Cable and Wire Manufacturer-ZW

- Tinned Cable

Tinned Cable

- According to IEC, ISO, Rosh

- Flame Retardant & PVC Cable

- Approved by CE, ISO, GB, BV

- Accept Lower MOQ

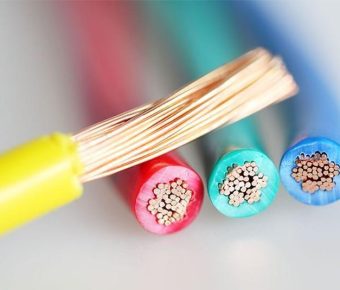

Tinned cable is an electrical conductor used in power transmission and distribution systems. Tinned copper wires are made by coating the copper wire with tin as a means of protection. They are highly resistant to atmospheric corrosion.

Conductor: Tinned

Insulation: PVC

Color of outer sheath: According to your demand

Package: 100meters

Tinned Cable: The Best Way To Get Started With Tinned Copper

Cables are copper wires insulated with PVC, rubber, LZSH, and other materials. Tinned cable uses a thin layer of metallic tin on the surface of copper instead of PVC insulation. The thin layer allows for better flow of electric current and shields out surrounding interference. The copper wire is suitable for use in cables. The conductor must be well plated because this allows it to resist corrosion and oxidation.

What is a tinned cable?

Tinned copper wire is a copper wire coated with a thin layer of tin to protect the copper from corrosion, reducing the service life of copper conductors in humid or rainy climates, high heat environments, and acid-like conditions.

The tin coating on this type of wire prevents rust and corrosion from occurring when exposed to acidic environments such as rain and snow or when it comes into contact with moisture in the ground.

Tinned copper also helps to prevent oxidation when it comes into contact with oxygen or air. Tinned copper is often used in applications with extreme heat or humidity, such as in marine applications or electrical wiring for homes built near bodies of water. We usually call it tinned wire marine.

Leading Cable and Wire Manufacturer-ZW Page Marine Wire According to IEC, GB, BS Standard Flame Retardant & LSZH Cable Approved by ISO, CE, UL Accept

The tinning process can be done by machine, depending on how much copper needs to be coated to meet the desired quality standard.

Tinned copper wire is often used to make electrical wire because it can easily be soldered to other wires and doesn’t rust as quickly as uncoated copper. The tin coating also makes it easier to bend the wire into different shapes without breaking it or causing it to stretch out over time. Tinned copper cable can also be used in wet environments because it resists rusting when exposed to water while still being conducive enough that electricity can flow through it smoothly.

Why use tinned Wire?

Tinned wire is primarily used to prevent oxidation and corrosion. In climates where copper is exposed to water for long periods, oxygen can combine with the metal to form copper oxide, which weakens the bond. The situation is worse if the wire comes into contact with salt water.

In addition to protecting against oxidation and corrosion, tinning makes it easier for the solder to adhere to the wire. It is easier for electricians to attach jumper cables or splices onto a length of tinned copper wiring.

Anyone who has worked on a boat knows that water can be a real problem for electrical connections. Considering how much of your boat is made from metal, it’s easy to see why the tinned wire is so famous for marine applications. The most common use for tinned wire is in marine wiring systems where it’s exposed to moisture and corrosive chemicals for extended periods.

Tinned wires have been used in electrical systems for over 100 years because they’re far less susceptible to corrosion than bare copper wires. Tinning also improves electrical conductivity by creating a barrier between the copper core and any air or moisture that may cause corrosion on its surface. Tinning also prevents oxidation within the insulation itself, which causes performance degradation over time when exposed to air or moisture.

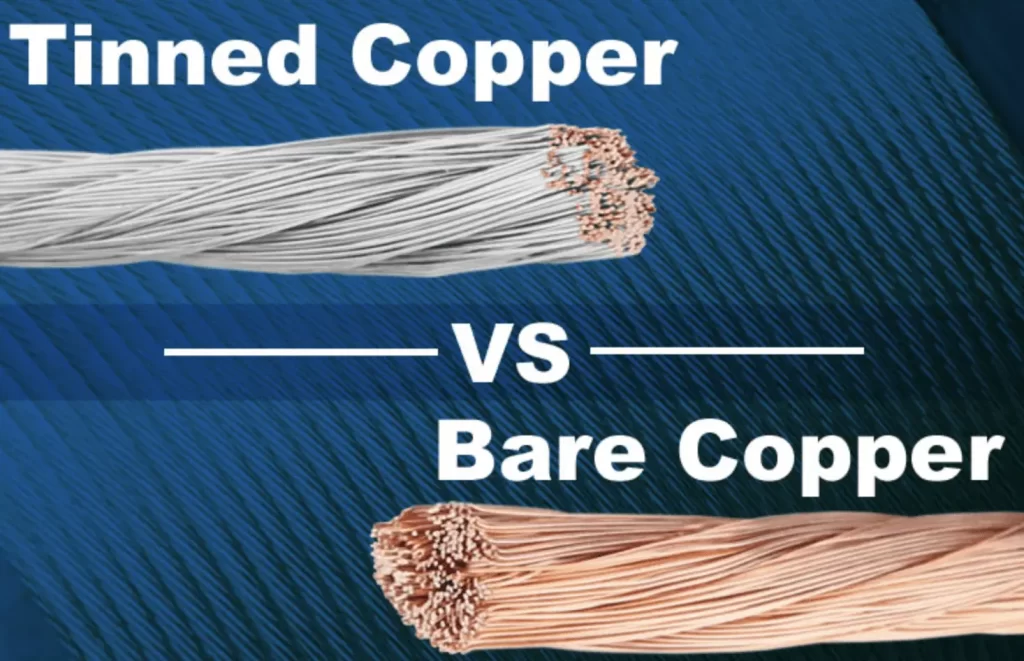

What is the difference between tinned and bare copper?

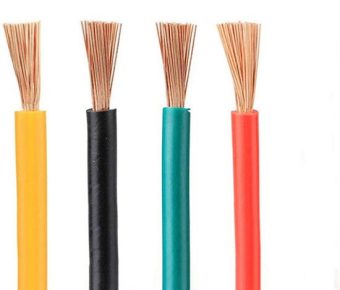

Copper is conductivity and durable. It is used as a building material. Copper wire can be used in electrical applications, while copper pipes are used in plumbing. There are also different kinds of copper wire and pipe, including bare and tinned copper.

The difference between bare and tinned copper is the coating on the metal. Bare copper has no coating, while tinned copper has a layer of tin applied to it. The purpose of this coating is to protect the metal from oxidation and corrosion.

Tinned Copper Wire

Tinned copper wire is used in most industrial applications because it is easily soldered. This type of wire is also called “tinned” or “tin-plated”. Tinning makes it easier to connect electrical components and allows for better conductivity. Tinning does not add any extra strength or durability to the wire. With proper care, tinned copper should last as long as bare copper without any problems.

Bare Copper Wire

Bare copper wire has not been tinned and cannot be soldered easily. However, it has several advantages over tinned copper in certain situations:

It is less expensive than tinned copper because it requires less manufacturing materials and labor.

The exposed metal provides an excellent heat sink, allowing it to dissipate heat much faster than tinned copper wires under high voltage pressure conditions.

Is tinned copper wire better?

Tinned copper wire for automotive has many benefits, including increased durability and resistance to corrosion. Tinning can improve performance in various applications, from marine environments to industrial settings. Some common uses for tinned copper wire include:

Electrical Wiring: Tinning improves conductivity and allows electricity to flow freely through the wires. Tinned copper cables are ideal for use in wire systems, where it helps prevent short circuits and other issues that could cause fires or explosions.

Marine Applications: Tinned cables are often used on boats because they are more resistant to corrosion than non-tinning options such as PVC insulation. In marine environments, tinning prevents rusting, which can lead to short circuits or damage in other ways.

Industrial Applications: Tinned cables are also commonly used in industrial settings subject to extreme weather conditions.

Tinned cable has an outstanding performance in an application at the moment. However, when choosing the conductor, you should emphasize the physical properties like resistivity and temperature. Tinned battery cable has high electrical conductivity, and it also has a reasonable price. Whether for hot or cold liquid, the tinned marine cable is flexible and durable with outstanding heat resistance and oxidation resistance characteristics if used in open air or wet conditions. ZW Cable will be your tinned copper wire suppliers. We will offer your tinned copper Wire price and tinned copper wire Specification when you send us an inquiry.