Aluminum vs copper wire as conductors are made from materials that allow for the flow of electrons or an electric current. Non-magnetic metals such as copper and aluminum are commonly used in conductor lines because they transmit electricity without becoming magnetized.

Conductors have various properties, such as conductivity, tensile strength, and weight: these should be considered when choosing which individual conductor to use in a given situation.

Also Read:Guide To Buying The Right ACSR Conductor

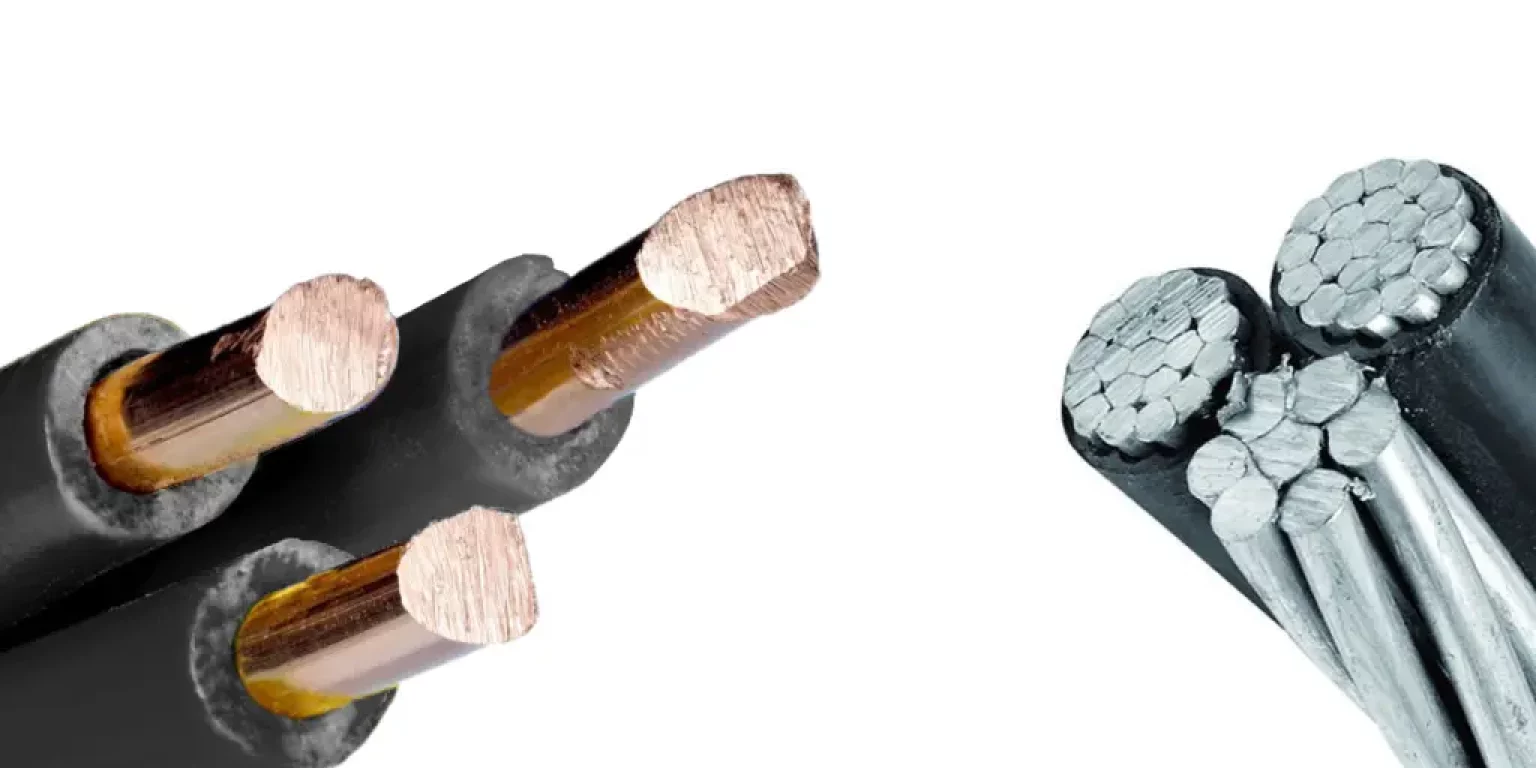

Aluminum vs Copper wire

Aluminum and copper are commonly used for different electrical applications in the construction industry. Aluminum and copper cables are the most common cable types used in building power systems. Although copper is more expensive than aluminum. Aluminum vs copper wire often chosen for its cost savings over long term installations. Because of its resistance to corrosion, copper is more commonly used for communications and control.

aluminum vs copper wire resistance:the differences between aluminum and copper cables are their current-carrying capacity and resistance. Copper cables have a current carrying capacity of about 40% higher than aluminum. The larger diameter of aluminum allows it to carry more current per unit length than copper of the same diameter. In addition, the resistance of aluminum cables is higher than that of copper (30% higher in the same cross-sectional area), so the conductivity of aluminum is much lower than that of copper.

When aluminum conductors are substituted for copper conductors, it is recommended that American wire gauges with aluminum conductors use two larger gauges than the size of the original copper conductor.

Because aluminum takes up more space and weighs less than copper, large cable tray will be required to carry the same amount of current. Because of this, constructing cables will be a little more difficult.

The disadvantage of aluminum wire:

Aluminum may be lighter, cheaper, and more pliable than copper, but it has drawbacks that may make it a less desirable option for some applications. It is a very soft metal that makes it difficult to terminate and increases the labor needed to install. Other drawbacks include:

- Long aluminum runs will encounter voltage drops almost double the value of copper cables. The increased drop can cause problems with sensitive equipment such as computers or televisions. Engineers often have to upsize the cable to compensate for the voltage drop.

- Vibrations can cause aluminum cables to fail, especially when installed in industrial buildings with high-frequency mechanical vibrations.

- The shorter service life of aluminum over copper may require more frequent replacement, which can become costly. Additionally, engineers and contractors may have to spend more time on maintenance due to the increased labor costs associated :with installing aluminum cables.

copper wire vs aluminum:Comparison

Parameters | Copper | Aluminim |

Symbol | Cu | AI |

Appearance | Sliver appearance | Red-Violet Appearance |

Melting Point: | 1,085 °C | 660.3 °C |

aluminum vs copper wire price | expensive | cheaper |

Cable classification | ABC Cable, ACSR, AAAC, |

Aluminum vs copper wiring in home application

Aluminum vs copper conductivity: Copper is known to have better conductivity than aluminum. Aluminum vs copper wire: copper is more efficient at conducting electricity.

Aluminum is not as efficient at conducting electricity as copper, which can cause problems when trying to power up your appliances. Aluminum vs copper wire, you may need more aluminum wiring to power all of your electrical devices, which can become costly and time-consuming.

Aluminum vs copper strength:In terms of strength and durability, aluminum doesn’t measure up to copper. Copper wiring is known for being incredibly strong and is extremely difficult to break or damage. Aluminum wiring is much easier to destroy, especially when it comes into contact with water. When it comes into contact with water, aluminum becomes vulnerable to corrosion, making the wiring completely useless!

Copper has better resistance than aluminum, greater mechanical strength, smaller surface area, and longer service life. If you choose the wire produced by ZW cable, the service life can be 70 years.

What are reasons for aluminum wire instead of copper?

When deciding whether to replace aluminum conductors with copper, it is important consider cost, weight and electrical conductivity.

Copper is heavier than aluminum. The specific gravity of copper is 8.9g.cm3, and that of aluminum is 2.7g/cm3, which means that the weight of a copper conductor is 3.3 times that of an aluminum conductor when the conductor specifications are the same.

However, the conductivity of aluminum is only 61% of that of copper, which means that the cross-section of aluminum conductors is 61% larger than that of copper conductors when the transmission current is the same.

Therefore, in terms of conductor weight, the weight of a copper conductor is about twice that of an aluminum conductor required to make both conductors have the same current-carrying capacity.

In addition, the price ratio of copper to aluminum is about 3.5, so the equivalent copper conductor costs seven times more than the aluminum conductor.

Of course, a simple cost comparison, as described above, does not tell the whole story. Since cable products have standard conductor specification restrictions, buying aluminum-core cables with conductivity equal to copper-core cables is impossible.

Therefore, a larger cross-section of aluminum conductors must be used if a cable is manufactured with aluminum conductors.

Under the same load capacity, the conductor cross-section of aluminum core cable should be twice as large as that of copper core cable. Since the cross-section of aluminum conductors is twice that of copper conductors, the insulation thickness, sheath thickness, and armored thickness need to be increased. Aluminum vs copper wire: the price advantage of aluminum compared to copper is modest because the conductor is only a small part of the cable cost.

Conclusion- Aluminum vs copper wire

Both Aluminum and copper are common materials used to make cables in wires in large buildings, industrial and residential applications. In pursuing your wire project, the best approach is to consider the needs of your project. After you have enough information or experience to understand the Aluminum vs copper wire, you can use our guide to help you quickly determine which option is right for your project. If you need further assistance, please contact us so that we can help guide you through this decision-making process.

Last Updated on November 10, 2022 by Richard