Copper cable is very ubiquitous in electrical projects. Electricians and engineers use it in almost all worksites, residential, commercial and industrial. However, for those of you that are new to the field, it may sometimes be confusing where to buy wires for your projects. You might wonder whether you should use solid or braided copper wire? You may even have questions about copper cable price and about which manufacturer to source your wires from.

We’ll cover all these questions, and more, in this Copper Wire Buyers Guide. By the time you read this Guide, you will know all there is to make intelligent and informed decisions about your copper cable requirements.

1.What is copper cable?

Copper cable is probably one of the oldest and most widely-used means of conducting electricity. It has been in use since the 1800s, ever since the invention of the telegraph and the telephone. According to some estimates, manufacturing copper wire cable uses over half of the copper mined. Because of its high conductivity characteristics, and high melting point, electrical project managers often favor copper cables over other available alternates.

The process of turning bricks of pure copper bricks into copper electrical cable is known as extrusion. At its simplest, this involves melting the bricks, called “ingot”, and stretching them through machines called extruders. Various manufacturing steps then produce different types of copper wire, including solid cables or stranded products, also called braided copper wire.

Due to qualities such as ductility (pliability), corrosion resistance, solderability and strength, the use of copper wire is almost ubiquitous. You’ll see them installed in power transmission, power generation, power distribution, residential and commercial building electrical use, and even in wiring components in equipment and circuitry.

2.Why copper is expensive?

Demand and supply are the underlying reasons that dictate copper cable price. Copper is one of the best conductors of heat and electricity, and therefore it is in high demand. High demand, therefore, commands higher prices. Also, copper wire cable uses lots of the underlying metal – copper – which is scarce in its production. Few jurisdictions mine copper today, and that scarcity drives copper cable price.

3.What are the advantages and disadvantages of copper cable?

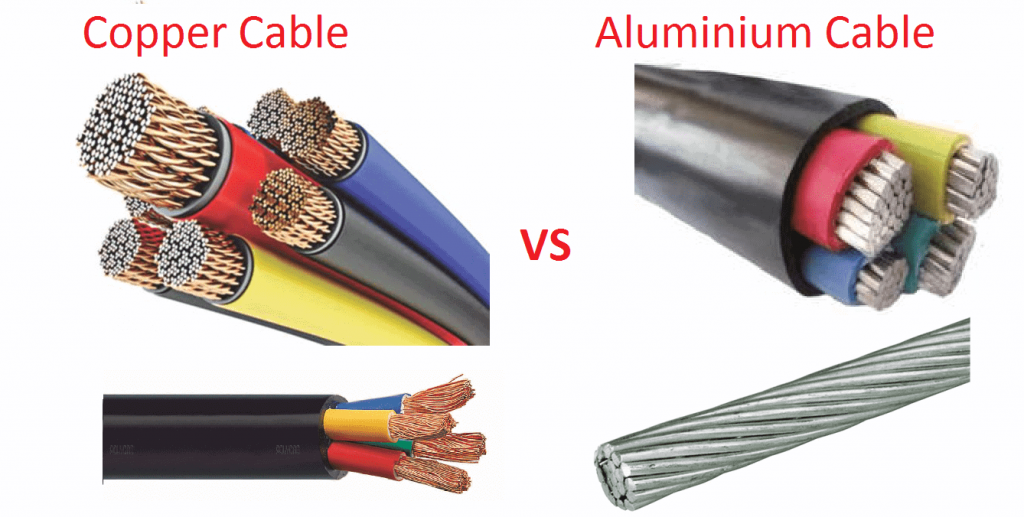

When making cabling choices for a project, for example whether to use 1/0 AWG copper wire or go with an aluminum cable of similar specification, engineers consider many factors. These may include the cost of the cable, ease of use, time to install, qualities of the underlying material (copper versus aluminum).

Engineers prefer to use copper cables because of the many advantages these wires bring to a project. Copper, as a metal, is rated very high (100%) for electrical conductivity. This means copper wire cable used for a wiring project brings high efficiency in output. Due to its higher tensile strength – (200–250 N/mm2 annealed versus aluminums 100 N/mm2) – Copper wire is also very tough, yet flexible. This means it isn’t brittle and won’t break when bent. However, due to this quality, it is also easy to work with in applications where, for example, electricians pass the insulated copper cable through bends and turns during installation.

Because of copper’s high melting point – 1981.4ºF/1083.0ºC (versus Aluminum: 1220ºF/660ºC) – copper electrical cable is ideal for applications that generate excessive amounts of heat. This makes copper wire the product of choice for more applications than other types of cables, for example when wiring heaters, furnaces and electric cooking appliances (stoves and ovens).

While insulated copper cable has many advantages, it’s direct competitor often is aluminum cables. In comparison to aluminum, copper cable is a heavier product to use. So, where weight is a critical factor, copper wire might not be the best choice. Also, aluminum is a cheaper substitute for copper. So, when there is a choice between using various types of copper wire versus their aluminum counterparts, especially if the installation is large, engineers and electricians may choose aluminum over copper, which makes the project more price-competitive.

4.If you can see a copper conductor in a cable what should you do with the cable?

Depending on the types of copper wire used in a project, there might be an inner mesh jacket, outer insulation, or both. In insulated copper cable, the mesh and outer insulation jacket is a safety measure, meant to restrict electrical current, flowing through the copper conductor, within the confines of the insulated jacket. This means that handling the cable does not pose a safety risk (shock) to anyone who touches the cable.

Sometimes, the jacket or insulation on solid or braided copper wire tears or it may be otherwise damaged, exposing the copper conductor within the insulated copper cable. This may happen due to various reasons, including excessive wear and tear, aging of the insulation or damage caused by rodents (rats, squirrels, household pets) gnawing at the cables. The best thing to do when confronted with this situation is to unplug the wire from its power source, and change/replace the cable before re-plugging it into the power source.

Using copper cable, in which you can see exposed copper conductors, is dangerous to anyone (humans or pets) who inadvertently touches the exposed conductor. Copper cables with frayed insulation and exposed conductors may also pose a fire hazard. That’s because the electrical current flowing through the conductor heats up the cable. With no insulation or barrier to contain that heat, any surface (like fabric, carpet or wood) touching the exposed conductor may catch fire.

4.Where to buy good Copper Cable?

Wondering where to buy wires for your next electrical project? To buy the best copper cables in the industry, you’ll need to source your wire from a manufacturer with lots of experience and production capabilities. Copper electrical cable is often a critical element in any electrification project. Therefore, your manufacture must have the highest standards of safety and quality assurance.

At ZW Cable, we specialize in manufacture of wire and cables. Whether you need 1/0 AWG copper wire for a critical project, or whether there’s a need for wires of various other specifications, we’ve got them right here for you. The types of copper wire we manufacture are suitable for use in a variety of projects, including commercial, residential and industrial use. Best of all, you’ll find our copper cable price more competitive and cost-effective than any other product of similar high-quality standards.

Last Updated on February 12, 2021 by Richard