Welcome to the ultimate guide on trailer wire colors! Every trailer needs functioning lights, brake systems, and electricity to stay safe on the road. The trailer also has to have adequate brake lights, turn signals and tail lights in order to avoid collision and traffic accidents. All breaks have to be electrified as well in order to work properly.

There are many colors and wires to work with, and this guide will show you everything about trailer wire colors. It’s possible to improve the functioning of the brake system and even disable the hydraulic breaks when you’re backing up. This is all done by changing the wiring system. This leaves the question: Where does one start learning how to do this?

Leading Cable and Wire Manufacturer-ZW Page Trailer Wire According to IEC 60092-3 Series Standard Flame Retardant

Introduction To Trailer Wire Color Systems

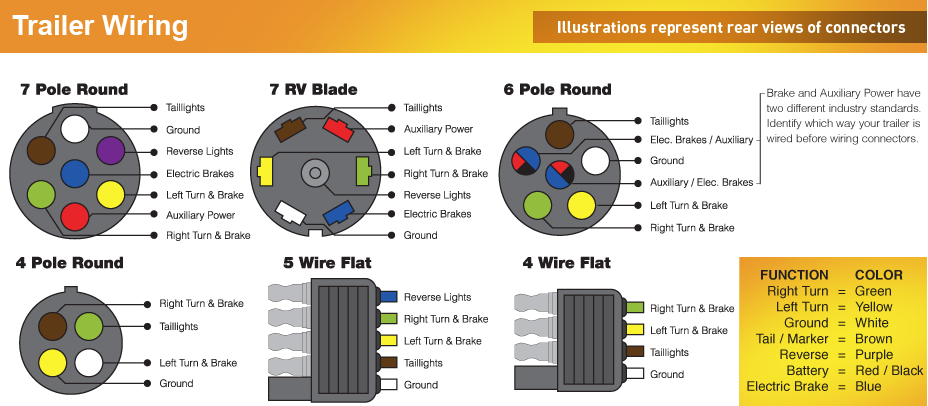

It’s easy to look at diagrams, but if you don’t know what you’re looking at you won’t get far. That is why this guide will serve you when you need a reminder of the basics. The basics include connecting 4-pin, 5-pin, and 7-pin connectors and knowing what each trailer wire colors mean. We should note that there are no ideal wiring systems for trailers and that all standards and wiring systems serve their own purpose.

In this guide, you’ll find the basic knowledge you need to wire your trailer and understand what you’re looking at when you use diagrams provided by your wire supplier. These are universal wiring standards that will work on virtually all trailers; however, you’ll still have to follow the diagrams provided by your supplier. If you want to get a broad overview of how each connector works, follow the guidelines laid out below.

Trailer Wires: 4 Core Trailer Wire Installation

The 4-core connector is the most basic connector you’ll find on all trailers. This connector is the easiest to install because you only have 4 functions. To make a trailer light work, you need 4 main LED lights: left signals, right signals, taillights, and brake lights. These lights can all be connected using a basic 4 core wires connector. The 4-pin connector is the minimal connector you’ll find on mid-sized and small trailers.

- The 4-pin connector is popular with all smaller forms of trailers, such as camper trailers, tiny boat trailers, utility trailers and similar. 4-core connectors are also the “easiest” to install compared to other pin connectors.

In terms of connector types, the “Flat” 4-pin connector is the most common 4-pin shape you’ll find on trailers (there are also round connectors). These 4-pin connectors are not very common on large trailers but they’re mainly used on smaller stationary trailers that are lightweight and don’t have break systems.

4 Core Trailer Wire Colors & Meaning

Each connector has a number of wires that you need to connect individually. In the case of the 4 wire trailer wire, the 4 individual colors signify different things.

- 1) The white color signifies the ground.

- 2) The brown color indicates tail lights or possible side markers.

- 3) The yellow color implies a left turn signal light.

- 4) The green color means a right turn signal or light.

5 Core Trailer Wire: Installation

The 5-core trailer wire is popular on heavier and bulkier trailers that exceeded 3000 lbs in weight. Trailers over this weight limit need to have breaks, and that’s why you need the extra connectors of the 5-core wire. While this regulation does not apply in all states, it’s still a good idea to install breaks on the trailer.

- 5-core trailer wires are essentially used to add breaks to traditional small trailers. If your trailer exceeds a certain weight, it’s time to install a brake system.

To install breaks, you’ll need to get a connector wire that has at least 5 pins (meaning 5 different trailer wire colors). While the connector is identical to the 4-pin connector, the 5-pin connector has another blue wire which gives drivers the power to operate breaks.

5 Core Trailer Wire Colors & Meaning

Each connector has a number of wires that you need to connect individually. In the case of the 5-core connector, the 5 individual trailer wire colors signify different things.

- 1) The white color signifies the ground.

- 2) The brown color means tail lights or possible side markers.

- 3) The yellow color indicates a left turn signal light.

- 4) The green color signifies a right turn signal or light.

- 5) The blue color suggests electric breaks or hydraulic release.

Pro Tip: If you’re looking at a diagram for a 7-core socket, because you purchase a 7-core wire (but you only require 5), you can simply use 5 pins and leave out the two others. The reverse can work in practice too: Let’s say you have a truck with a 7-pin socket but you don’t want to use the 2 remaining pins.

All you have to do is leave them out and connect your 5-pin trailer wire, removing 2 of the wires. You’ll accomplish the same thing, but the wires will be compatible with the 5-pin system of your trailer. The wires do the same thing and it’s easy to leave out certain wires if you need them in this situation.

7 Core Trailer Wire: Installation

The 7 core trailer wire is the largest wires set you can purchase for trailers, and this wire provides the full range of light and break services required by a large trailer. The 7-core wire can work on a smaller trailer if you only connect 4 or 5 wires, but it’s recommended for large trailers such as RVs and the kind of trailers that a person could technically reside in.

- The 7-core trailer wire is ideal for all large trailers that have a lot of electronics and need adequate signalling.

- 7-core wires are identical to 4 and 5-pin wires but they add backup lights and auxiliary power. The 7-pin connector is a bit more complex, yet the connection principles are the same.

Industrial standards for 7-core trailer wires are the same and you’ll find them easy to interchange between different trailer wires. The extra wires on the 7-core trailer are for auxiliary power and back-up lights which are not present on 5-core connectors. If you want only one of those, you can leave the other one out. It’s possible to leave one of these wires blank, depending on your individual needs.

7-Core Trailer Wire Colors & Meaning

Every connector has a number of wires that you need to connect individually. In the case of the 5-pin connector, the 5 individual trailer wire colors signify different things.

- 1) The white color signifies the ground.

- 2) The brown color means tail lights or possible side markers.

- 3) The yellow color indicates a left turn signal light.

- 4) The green color shows a right turn signal or light.

- 5) The blue color signifies electric breaks or hydraulic release.

- 6) The red color implies auxiliary power (usually 12V power).

- 7) The purple color suggests back-up lights. This color may vary based on the manufacturer.

Trailer Wire Size & Connection

If you’re wondering what size your trailer wires should be, the biggest difference in wires is the gauge. This is a measurement used to signify the power that can be transmitted through each wire. The most popular wire sizes for trailers are 12-gauge, 14-gauge and 16-gauge. If you only need the basics such as light systems for your small trailer, you could do away with a small 12-gauge or 14-gauge wire because LEDs don’t require a lot of power.

However, for all large 5-core or 7-core connectors that require powerful brake systems, we recommend a 12-gauge wire size. The 12 gauge wire is different in the sense that it’s thicker and more robust – making it more reliable for securing auxiliary power and brake systems. The small difference in price is justified for the peace of mind it gives you on the road. However, if you want to save a bit of money you can always opt for a 16 gauge wire.

You may be interested in:12 Gauge Wire-All About Usage and Appropriate Areas of Application

If you’re also replacing the light systems on your trailer, it’s best to get submersible LEDs that can withstand moisture. While the trailer doesn’t function as a water boat, you still need water resistance to withstand moisture. These protective LEDs may cost a bit more, but they’re well worth the price difference to secure your brake system on the road.

Trailer Wire Color Signify

All trailer wires have 4 essential color wires that you can connect in the same universal manner on all large trailers. Here is the critical information you need to know about each wire:

1) White Wires

The white wire is the first wire you need to connect to the trailer’s battery minus side. This wire is called the ground/negative wire and it needs to go directly to the lights and breaks. In some cases, the white wire may be connected to the utility power.

The white wire must be the biggest or as big as the largest wire in the set of wires. Most trailers have the white wire connected to the mainframe and then the ground (with all accessories attached) is connected to that mainframe as well. This method is effective but the ground circuits cause a lot of electrical issues.

The optimal way to run the white wire is to connect each light from the ground directly to the white. This approach is a bit harder but it saves a lot of repair work later down the line. For LEDs only, a small white wire will suffice but you may need a large wire for additional things such as auxiliary power.

2) Brown Wires

The brown wire is essential for the front lights that have to be activated when you’re on the road. This wire is responsible for securing the front running lights, a small segment of the taillights and corner markers. Optionally, the brown wire can be used to connect the 3 central lights from the back of the trailer.

- These 3 lights are not always required for small trailers, but you should check with your state regulations to see if you need them. The brown wire feeds these lights while the white one feeds the ground.

In terms of size, the brown wire doesn’t have to be oversized and it can be one of the smallest wires. As a rule of thumb, check the power requirements of your LEDs to determine the size you need. If you have a small trailer with not a lot of power requirements, you can do with a smaller wire. If you have a larger RV trailer you may need a larger brown wire.

3) Blue Wires

The blue wire is the wire responsible for the brake system of the car, and sometimes the reverse lights. In some cases, the blue wire can enable trailers to disable the breaks when they’re reversing (if the trailer uses hydraulic breaks). If you want to use the blue wire for this purpose, you’ll need to connect it to the reverse lights of the vehicle.

In essence, the blue wire is a wire that is connected to the brake controller and used to control the brake system of the trailer. In terms of size, you shouldn’t opt for a small blue wire because this wire has direct control over your brake system. A 16-gauge blue wire is ideal and will function well on everything from 5-core connectors to 7-core connectors.

4) Red Wires

The red wire is a wire found on 7-core connectors, although in some cases this wire can be black. This wire is responsible for the auxiliary power of the trailer and it provides access to the positive power of the vehicle. Auxiliary power is essential for charging the trailer batteries, powering the interior lights, powering trailer accessories, and more.

The routing for this wire is the most complex because each individual trailer has a different routing method. If your trailer doesn’t require separate power, you can leave this wire out. If you do use it, make sure you add an extra layer of protection for short fuses. In terms of size, you need power that is reflective of the power demands of the vehicle in order to avoid draining the tow energy battery.

Introduction To Trailer Wire Color Systems

It’s easy to look at diagrams, but if you don’t know what you’re looking at you won’t get far. That is why this guide will serve you when you need a reminder of the basics. The basics include connecting 4-pin, 5-pin, and 7-pin connectors and knowing what each trailer wire colors mean. We should note that there are no ideal wiring systems for trailers and that all standards and wiring systems serve their own purpose.

In this guide, you’ll find the basic knowledge you need to wire your trailer and understand what you’re looking at when you use diagrams provided by your wire supplier. These are universal wiring standards that will work on virtually all trailers; however, you’ll still have to follow the diagrams provided by your supplier. If you want to get a broad overview of how each connector works, follow the guidelines laid out below.

Trailer Wires: 4 Core Trailer Wire Installation

The 4-core connector is the most basic connector you’ll find on all trailers. This connector is the easiest to install because you only have 4 functions. To make a trailer light work, you need 4 main LED lights: left signals, right signals, taillights, and brake lights. These lights can all be connected using a basic 4-wire connector. The 4-pin connector is the minimal connector you’ll find on mid-sized and small trailers.

- The 4-pin connector is popular with all smaller forms of trailers, such as camper trailers, tiny boat trailers, utility trailers and similar. 4-core connectors are also the “easiest” to install compared to other pin connectors.

In terms of connector types, the “Flat” 4-pin connector is the most common 4-pin shape you’ll find on trailers (there are also round connectors). These 4-pin connectors are not very common on large trailers but they’re mainly used on smaller stationary trailers that are lightweight and don’t have break systems.

4 Core Trailer Wire Colors & Meaning

Each connector has a number of wires that you need to connect individually. In the case of the 4-core connector, the 4 individual colors signify different things.

- 1) The white color signifies the ground.

- 2) The brown color indicates tail lights or possible side markers.

- 3) The yellow color implies a left turn signal light.

- 4) The green color means a right turn signal or light.

5 Core Trailer Wire: Installation

The 5-core trailer wire is popular on heavier and bulkier trailers that exceeded 3000 lbs in weight. Trailers over this weight limit need to have breaks, and that’s why you need the extra connectors of the 5-core wire. While this regulation does not apply in all states, it’s still a good idea to install breaks on the trailer.

- 5-core trailer wires are essentially used to add breaks to traditional small trailers. If your trailer exceeds a certain weight, it’s time to install a brake system.

To install breaks, you’ll need to get a connector wire that has at least 5 pins (meaning 5 different trailer wire colors). While the connector is identical to the 4-pin connector, the 5-pin connector has another blue wire which gives drivers the power to operate breaks.

5 Core Trailer Wire Colors & Meaning

Each connector has a number of wires that you need to connect individually. In the case of the 5-core connector, the 5 individual trailer wire colors signify different things.

- 1) The white color signifies the ground.

- 2) The brown color means tail lights or possible side markers.

- 3) The yellow color indicates a left turn signal light.

- 4) The green color signifies a right turn signal or light.

- 5) The blue color suggests electric breaks or hydraulic release.

Pro Tip: If you’re looking at a diagram for a 7-core socket, because you purchase a 7-core wire (but you only require 5), you can simply use 5 pins and leave out the two others. The reverse can work in practice too: Let’s say you have a truck with a 7-pin socket but you don’t want to use the 2 remaining pins.

All you have to do is leave them out and connect your 5-pin trailer wire, removing 2 of the wires. You’ll accomplish the same thing, but the wires will be compatible with the 5-pin system of your trailer. The wires do the same thing and it’s easy to leave out certain wires if you need them in this situation.

7 Core Trailer Wire: Installation

The 7 core trailer wire is the largest wires set you can purchase for trailers, and this wire provides the full range of light and break services required by a large trailer. The 7-core wire can work on a smaller trailer if you only connect 4 or 5 wires, but it’s recommended for large trailers such as RVs and the kind of trailers that a person could technically reside in.

- The 7-core trailer wire is ideal for all large trailers that have a lot of electronics and need adequate signalling.

- 7-core wires are identical to 4 and 5-pin wires but they add backup lights and auxiliary power. The 7-pin connector is a bit more complex, yet the connection principles are the same.

Industrial standards for 7-core trailer wires are the same and you’ll find them easy to interchange between different trailer wires. The extra wires on the 7-core trailer are for auxiliary power and back-up lights which are not present on 5-core connectors. If you want only one of those, you can leave the other one out. It’s possible to leave one of these wires blank, depending on your individual needs.

7-Core Trailer Wire Colors & Meaning

Every connector has a number of wires that you need to connect individually. In the case of the 5-pin connector, the 5 individual trailer wire colors signify different things.

- 1) The white color signifies the ground.

- 2) The brown color means tail lights or possible side markers.

- 3) The yellow color indicates a left turn signal light.

- 4) The green color shows a right turn signal or light.

- 5) The blue color signifies electric breaks or hydraulic release.

- 6) The red color implies auxiliary power (usually 12V power).

- 7) The purple color suggests back-up lights. This color may vary based on the manufacturer.

Trailer Wire Size & Connection

If you’re wondering what size your trailer wires should be, the biggest difference in wires is the gauge. This is a measurement used to signify the power that can be transmitted through each wire. The most popular wire sizes for trailers are 12-gauge, 14-gauge, and 16-gauge hook up wire. If you only need the basics such as light systems for your small trailer, you could do away with a small 12-gauge or 14-gauge wire because LEDs don’t require a lot of power.

However, for all large 5-core or 7-core connectors that require powerful brake systems, we recommend a 14 gauge wire size. The 14 gauge wire is different in the sense that it’s thicker and more robust – making it more reliable for securing auxiliary power and brake systems. The small difference in price is justified for the peace of mind it gives you on the road. However, if you want to save a bit of money you can always opt for a 16 gauge wire.

If you’re also replacing the light systems on your trailer, it’s best to get submersible LEDs that can withstand moisture. While the trailer doesn’t function as a water boat, you still need water resistance to withstand moisture. These protective LEDs may cost a bit more, but they’re well worth the price difference to secure your brake system on the road.

Trailer Wire Color Signify

All trailer wires have 4 essential color wires that you can connect in the same universal manner on all large trailers. Here is the critical information you need to know about each wire:

Related Post: Electrical Wire-Choice May Impact Your Wiring Project

1) White Wires

The white wire is the first wire you need to connect to the trailer’s battery minus side. This wire is called the ground/negative wire and it needs to go directly to the lights and breaks. In some cases, the white wire may be connected to the utility power.

The white wire must be the biggest or as big as the largest wire in the set of wires. Most trailers have the white wire connected to the mainframe and then the ground (with all accessories attached) is connected to that mainframe as well. This method is effective but the ground circuits cause a lot of electrical issues.

The optimal way to run the white wire is to connect each light from the ground directly to the white. This approach is a bit harder but it saves a lot of repair work later down the line. For LEDs only, a small white wire will suffice but you may need a large wire for additional things such as auxiliary power.

2) Brown Wires

The brown wire is essential for the front lights that have to be activated when you’re on the road. This wire is responsible for securing the front running lights, a small segment of the taillights and corner markers. Optionally, the brown wire can be used to connect the 3 central lights from the back of the trailer.

- These 3 lights are not always required for small trailers, but you should check with your state regulations to see if you need them. The brown wire feeds these lights while the white one feeds the ground.

In terms of size, the brown wire doesn’t have to be oversized and it can be one of the smallest wires. As a rule of thumb, check the power requirements of your LEDs to determine the size you need. If you have a small trailer with not a lot of power requirements, you can do with a smaller wire. If you have a larger RV trailer you may need a larger brown wire.

3) Blue Wires

The blue wire is the wire responsible for the brake system of the car, and sometimes the reverse lights. In some cases, the blue wire can enable trailers to disable the breaks when they’re reversing (if the trailer uses hydraulic breaks). If you want to use the blue wire for this purpose, you’ll need to connect it to the reverse lights of the vehicle.

In essence, the blue wire is a wire that is connected to the brake controller and used to control the brake system of the trailer. In terms of size, you shouldn’t opt for a small blue wire because this wire has direct control over your brake system. A 16-gauge blue wire is ideal and will function well on everything from 5-core connectors to 7-core connectors.

4) Red Wires

The red wire is a wire found on 7-core connectors, although in some cases this wire can be black. This wire is responsible for the auxiliary power of the trailer and it provides access to the positive power of the vehicle. Auxiliary power is essential for charging the trailer batteries, powering the interior lights, powering trailer accessories, and more.

The routing for this wire is the most complex because each individual trailer has a different routing method. If your trailer doesn’t require separate power, you can leave this wire out. If you do use it, make sure you add an extra layer of protection for short fuses. In terms of size, you need power that is reflective of the power demands of the vehicle in order to avoid draining the tow energy battery.

Last Updated on August 28, 2022 by Richard