In recent years, the most active new product in the field of cables should be a mineral insulated cable. Many cable manufacturers may also often be able to come into contact with mineral cables. But I think that for the cable field newcomers, the mi cable is still relatively unfamiliar, so ZW cable would like to share the following mi cable products for you.

1.What is Mineral Insulated Cable?

The mineral cable is the earliest fire cable, originated in Switzerland, later developed by the United Kingdom into a specific scale and custom fire standard bs6387 standard.Micc cable generally refers to mineral insulated cable. Mi cable can also be divided into mineral insulated cable and mineral fire cable.

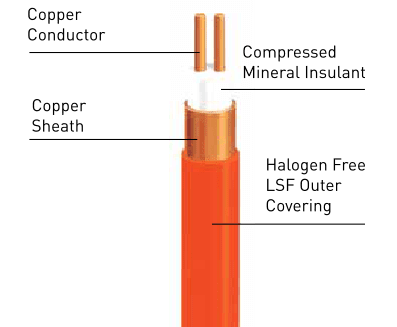

Micc cable is an inorganic material cable. The outer layer of the cable is a seamless copper sheath. Between the sheath and the metal core is a layer of closely compacted magnesium oxide insulation layer. Mineral insulated cables are divided into different uses: wiring cables, heating cables, and heating thermocouple cables and compensation cables, special cables, etc.

2. what is mineral insulated cable used for?

Mineral insulated copper cable itself does not cause fire, is not likely to burn, can continue to maintain power supply in the case of fire close to the melting point of copper, is a real sense of fire-resistant cable. They used high-rise buildings, petrochemicals, airports, tunnels, ships, offshore oil platforms, aerospace, iron and steel metallurgy, shopping centres, parking lots and other occasions.

Although the mineral insulated cable performance is strong, most people think that the mic cable price is high and not used. In recent years, with the continuous efforts of manufacturing plants and material suppliers, the price of mineral insulated cable is continuously approaching ordinary cable costs.

ZW cable also through the continuous introduction of advanced technology and equipment to improve the mineral insulated power cable’s quality. At the same time, with a more affordable price to promote this quality cable, I hope this cable in the future can be more widely spread to our lives, to protect our life safety from contributing!

3. How to make mineral insulated cable?

Mineral insulated cable production process and equipment and needed more professional. Let us introduce three ways of mineral insulated cable production processes.

The first process is also the earliest and most commonly used porcelain column assembly method. Most of the production and manufacturing mineral insulated cable manufacturers are currently using this process.

It uses sintered magnesium oxide porcelain column hand-filled to the copper tube and copper rod between and after a series of drawing annealing the final product. The biggest drawback of this cable production and manufacturing process is the labour intensity and low production efficiency.

The second process is called the magnesium oxide powder filling method. The standard image analogy is like a funnel between the vertical copper rod and the copper tube filled with magnesium oxide powder. This processing can make the conductor and sheath concentricity better, but this production equipment is almost rare. In the filling process, magnesium oxide powder may be damp. The production workshop requires to be sealed and dry. The air humidity requirements are more strict.

The third production process is the world’s most advanced copper belt longitudinal welding method. This mineral insulated cable production process principle is that the copper belt and copper rod can be infinitely welded and let the copper belt longitudinal welding moulding wrapped around the copper rod. In the copper rod and welding between the copper belt filled with magnesium oxide powder. The main production equipment of mineral insulated cable is a wire drawing machine, extruder, cable machine, braiding machine, fork twisting machine, inverted wire machine, wire measuring machine, bundling machine, etc.

There is also the introduction of advanced magnesium oxide powder infusion equipment, processing mineral insulation layer equipment, longitudinal copper sheathing equipment, etc. According to the process of choosing different equipment. There are also these special cables for the working environment requirements are even relatively high.

4. Mineral Insulated cable price

The price of mineral cable is between $90 and $200.There will have a cheaper price in the market. It is depending on the size and quality of the material. Therefore, we recommend comparing several manufacturers. Let cable manufacturers send your samples, and then compare the sample. Choose which sample is qualified and buy from these Manufacturers.

Of course, if you can buy directly from mineral insulated Manufacturers, we will also provide samples for testing and provide you with some cable solutions. Let you fully believe that our products and services. Our cable service life is 70 years. The mineral cable is the most expensive of all cables, so it is 30 percentage points more expensive than PVC cable and cross-linked cable and 15 percentage points more expensive than low smoke and halogen-free cable. We will also inform that day that the price is the lowest according to the LME. We will tell you the best time to purchase.

5. How to install mineral insulated cable?

1. Cut a trace line in the cable with a pipe cutter according to the required length.

2. Use a pair of diagonal pliers to twist the sheathed copper skin clockwise between the jaws, clamp the edge of the sheathed copper skin step by step, and rotate and peel the clad copper skin at a small angle until the cutting mark is reached.

3. Thoroughly remove the magnesium oxide insulation from the bare wire with a clean, dry cloth, then place the harness head on the cable and screw the brass sealing cup vertically on the copper sheath of the cable sheath. First, check the sealing cup’s verticality by twisting it by hand and sliding the bundle head over the sealing cap. Once truly vertical, clamp the sealing cup’s knurled seat with a pipe wire clamp and continue the installation until the end of the tiger skin is below the partial thread inside the sealing cup!

4. At approximately the distance, starting from the cable trip, heat the cable 600 mm using a torch flame and continuously move the flame to the cable’s open end to remove moisture. Remember to move the flame to the open end of the cable only. Otherwise, moisture will enter the cable.

5. Use an ohmmeter to measure the insulation resistance between the core and the sheath. If the measurement result meets the requirement, the sealing paste can be injected into the sealing cup.

6. Note that sealing paste should be added gradually from one side, not too fast, to expel air. When the sealing paste is completely filled, press the cup cover and then cover the wire core with a heat-shrinkable sleeve.

6. A comprehensive evaluation of the mineral cable

The cable is a real green and safe product. Compared with the current more “environmentally friendly” halogen-free low-smoke cable. Mineral insulated cables significantly improve their electrical and mechanical properties and truly achieve halogen-free, smoke-free and harmless, and eliminate the residual toxins in halogen-free low-smoke cables. And completely overcome the smoke and toxicity caused by the flame combustion of multiple halogen-free low-smoke cables.

It is a collection of plastic cable performance advantages. You can not just think of the cable is a high-temperature or fire-resistant cable. Fire” is only one of its intuitive performance. Non-combustible, explosion-proof, anti-corrosion, waterproof, anti-magnetic, anti-mechanical damage, high flow capacity, overload capacity, etc., the effect of any one performance is far better than PVC cable.

The product is no longer mainly used in fire-fighting systems, due to its superior performance-price will replace the halogen-free low-smoke cable, fire-resistant cable, flame retardant cable, bus bar and other products

With the development of the construction industry, mineral cables are increasingly in construction. Only strengthen familiarity with the installation method of mineral cable and achieve the safety and beauty of mineral insulated cable. It can also reduce the intermediate connectors, save materials and bring convenience to the construction.

Last Updated on June 23, 2022 by Richard