1.What is EPR Cable?

Ethylene propylene rubber (EPR) is a kind of binary ethylene-propylene rubber (EPM) and tertiary ethylene-propylene rubber (EPDM), is a saturated rubber formed by copolymerization of ethylene, propylene, and a small number of diene monomers, due to its excellent electrical insulation, good resistance to ozone, humidity, heat, cold and aging properties, has been widely used in low and medium voltage, high voltage and even ultra-high-voltage cables.

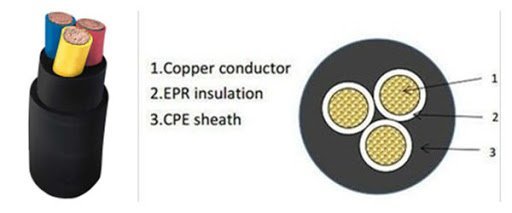

2.EPR Cable Specification

Ethylene Propylene Rubber (EPR), whose full name is cross-linked ethylene-propylene rubber, has the stability of oxygen and ozone resistance and partial discharge and has excellent cold resistance, maintaining good flexibility even at -50℃.

Also, it has excellent stability against weathering and light. In particular, it does not contain halogen and has flame retardant properties. The ethylene-propylene rubber insulated cable with chlorosulfonated polyethene sheath is suitable for places requiring flame retardancy.

Epr insulated cable is not yet widely used in China but has long been used in large quantities abroad, especially in Europe. It has excellent electrical and mechanical characteristics and has good high-temperature resistance even in humid environments. Epr insulated cable allowable operating temperature up to 90 ℃, short-circuit thermal stability of the permissible temperature of 250 ℃.

A kind of irradiation-resistant low smoke halogen-free flame retardant ethylene-propylene rubber cable material preparation method, through the input of ethylene-propylene rubber, aluminum hydroxide, silicone flame retardant synergist, lead compounds, antioxidant, anti-copper agent, γ-ray absorber, liquid peroxide vulcanizing agent, and phenolic heat stabilizer into the compacting machine, heating, and mixing, and then through the twin-screw extruder air-cooled made.

3.Epr insulated cable Features

The dielectric loss factor of ethylene propylene rubber is large, so it is only used in mv 105 15kv cable with voltage levels below 138kV. Due to the good water resistance of ethylene-propylene rubber, so ethylene-propylene rubber cable is suitable for submarine cable, and because ethylene-propylene rubber has good soft characteristics, so more suitable for use in marine and ship laying.

4.Ethylene propylene rubber cable type

There are many types of EPR Cable, and different ethylene content, diolefin type, and its content, rubber molecular weight, and its distribution will directly affect the performance of the rubber. Therefore, the choice of EPR type is very important for the design of a product for a specific application. Generally speaking, the higher the vinyl content in EPDM, the better its dielectric and mechanical properties, but its addictive properties and low-temperature flexibility become worse. As a cable material, it is usually appropriate to use low Menny viscosity, vinyl content between 65% and 75% of the low molecular weight, a semi-crystalline polymer as the main material. Wire and cable with EPR mainly for foreign products

5. EPR Flame retardant performance

EPR cable can be flame retarded by adding organic halogen flame retardants or inorganic flame retardants, and the common organic halogen flame retardants for EPR cables are dicyclopentadiene and decabromodiphenyl ether, whose flame retardant mechanism is mainly through the release of non-flammable hydrogen halide, diluting combustible gases, on the one hand, isolating air and heat on the other, and capturing free radicals to inhibit combustion chain reactions, so as to achieve effective flame retardancy.

When the weight ratio of organohalogen flame retardant to antimony trioxide is between 2 and 5, the halogen flame retardant only needs 15 to 40 parts to achieve the flame retardant effect. The disadvantage of organic halogen flame retardants is that once the fire produces strong corrosive hydrogen halide gas, causing secondary disasters, inorganic flame retardants can overcome the above disadvantages.

6. The prospect of flame retardant ethylene-propylene rubber cable material

EPR has been widely used in power cables, mining cables, marine cables, motor wires and device cables, and other heat-resistant and high-voltage products, the use of about 10 % to 15 % of the total amount of rubber in the cable industry. In China, the EPR insulation used in wire and cable was 0.4 million tons in 1985 and will reach 1.15 million tons in 2000 with an annual growth rate of 8%.

Flame retardant treatment of EPR can broaden the application of EPR cable on special occasions, especially low smoke halogen-free flame retardant EPR cable can be used in warships, underground passenger stations, underground coal mines, instrumentation rooms, and other places. The International Electrotechnical Commission has developed a flame retardant cable burning, smoke, toxicity, and other test standards, medium voltage cable and low-voltage cables, offshore oil platforms with cables, subway cables, and nuclear power plants with cables are urgently promoting the use of halogen-free flame retardant cables.

The development direction of low smoke halogen-free flame retardant EPR cable is to further improve the overall performance of the cable (including flame retardant performance, mechanical properties, electrical properties, processing performance, etc. while reducing production costs and expanding the application areas. EPR cable development of low smoke and halogen-free flame retardant. EPR insulation materials to meet the needs of the modern wire and cable development, with potential economic benefits and social value. As an EPR cable manufacturer, ZW cable will be your best choice. We will offer your best rate.

Last Updated on June 27, 2022 by Richard