- Leading Cable and Wire Manufacturer-ZW

- 35KV High Voltage Cable

High Voltage Cable

- According to IEC 60502-2 and GB Standard

- 3 Cores

- Approved by BV, ISO, SGS

- Black and Red Color

High-voltage cable is a kind of electrical cable, which is used to transmit power cables between 1kv-1000kv. It is mostly used in power transmission and distribution.

Conductor: Copper or Aluminum Conductor

Insulation: XLPE

Amour: steel tape amour

Sheath: PVC

Rated voltage:18/30KV 26/35k

High Voltage Cables- Its Amazing Features And Benefits

With the continual advancement of technology, there was a need for power transmission at high voltage to power most inventions. We have seen a constant shift from several generations of power to a more safe and convenient way to provide electricity. Electricity, which holds a high sway in the electronic, electrical and technological world, is one component that would rarely go away. New modes and channels of its conduction and distribution are being innovated all over the world. The transmission of electricity through high voltage cable has become a mainstay, and that is why we would be looking into its mode of operation.

High voltage cables, also referred to as HV cables, are still the best, strongest, and most reliable way to transport voluminous electricity voltage. The voltage is 35kv. As a leading supplier, ZW CABLE would provide as much information as possible in this post, and we hope you pick up a thing or two.

Understanding High Voltage

To understand high voltage cables, we would try as much as possible to break them down to it’s simplest form. This way, it rings close to home and would create a better picture of how you’d view this electrical phenomenon. Now you might have seen these signs that warn trespassers to keep off with a bold sign in red that has a thunder or volt sign and most times with the inscription “Danger, High Voltage.”

These signs specify that the region about to be entered comprises high voltage capable enough to bring danger to anyone who has the slightest contact. These locations have massive wires and spark and threaten at the closest contact of any human conductor. They are packed with so much electricity to power a city, making the slightest contact with any human or animal without the right apparatus toast.

High Voltage, which is being conducted and transmitted in the above explained, is a range of electrical volts that have superseded the average set volume required for human consumption. With a range of about 1000 – 35000 volts, high voltage is dangerous to human contact and tougher to transport over great distances hence the need for high voltage power cables built for such.

What is High Voltage Cable?

Now that we have a better understanding of high voltage breaking down high voltage cables should be easier. As stated earlier, we mentioned that high voltage power cable goes above the threshold of human and home consumption as it can cause loads of damage. So need for a specially built medium called medium voltage cables is required.

Also Read: Medium Voltage Cables: A New Standard In Power Transmission

So what are high voltage cables? High Voltage cables are conductors fitted with insulators, cables, and joints to help ensure the safe distribution and containment of high voltage over a long distance. The insulator, which is a component due to its protective nature, keeps water away from the electrical volts when used in a place that could bring about their contact, e.g., underground or during rainfall. Although different high-voltage cables carry out various jobs, they all undertake the same responsibility of building a barrier between conductors such as humans or animals and death-inducing voltages. Usually, we call it 35kv cable.

High voltage cables are usually fitted with a metallic layer of cable terminal and joint for improved safety, thereby neutralizing the standard insulation’s dielectric stress. Several other factors are also responsible for this insulation as our atmosphere is saturated with electrical discharges that can trigger the escape of electrical volts from the high voltage cables.

The prices of high voltage vary depending on the type but can be as high as $32. High voltage cables types include

- Automotive High voltage cables

- Instrumentation cables

- power transmission cables

- X-ray cables

What is the Purpose of a Semiconductor in a High Voltage Cable?

High Voltage electrical cable is known to possess a dangerous tendency when not adequately contained, as the slightest expression can bring about unplanned circumstances. This has led to constant research on how to contain this current in high voltage power cables. During underground high voltage wire installation, access to these high voltage wires’ routine checkups is limited, resulting in a lasting solution.

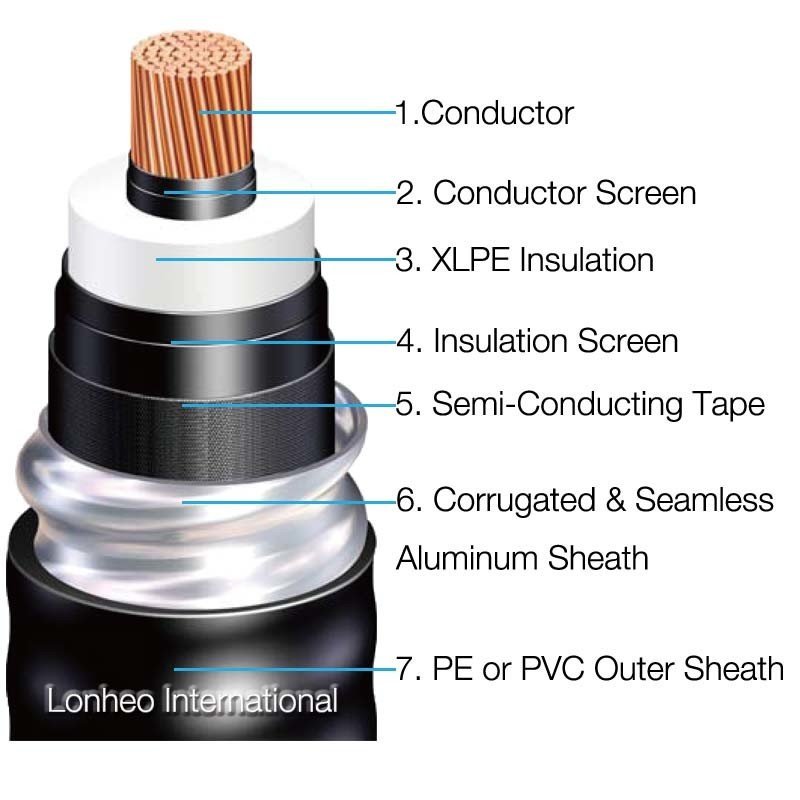

High Voltage cable manufacturers now include semiconductors to properly secure and efficiently provide an environment for electrical field distribution. High voltage wire Manufacturer introduced a new shield due to the several air gaps found in high voltage cables due to the conductor and insulator’s unevenness. Semiconductors provide that shield between both components and serve as a balancing factor between the conductor and the insulating layer, thereby eradicating partial discharge.

This semiconductor, which also serves as protection, doesn’t come with a metal sheath. However, a metal sheath is usually wrapped with copper tape to serve as the capacitive current source. This way, the conductor and the insulator are distressed, creating an avenue to allow the free flow of electrical current. So ultimately, the semiconductor acts as an intermediary between both the insulator and the conductor. The sheath can be PVC insulation.

How to test High Voltage Cables

Testing cables can be a challenging and delicate task, as it involves lots of precision and accuracy. It is necessary to monitor slight mistakes that could cause harm during the installation of high voltage cables with a specific that would give the cables quality assurance. Since we have earlier stated that high voltage is dangerous to living things, a comprehensive test is required. The faults associated with high voltage cable damage aren’t noticeable. However, there are ways through which they can be detected. The primary reasons to test cables do not exceed the three main features: Conformity, quality, and functionality of the high voltage cable.

Most high voltage cable testing undergoes 5 phases before being deemed durable and quality enough for such tasks. The test is as follows:

- Insulation

The high voltage cable insulation test can confirm the cable’s resistance level—this test occurs in direct current and combines a high voltage and short circuit test. During the test, the voltage is usually increased at intervals to check for short circuits. The HV cable is said to pass the test in the absence of no short circuits.

- Continuity

The continuity test mostly focuses on testing the resistance of the high voltage cables. The test occurs from a range of 1ohm to about 250 ohms.

- Phasing

This test uses a Phasing meter, and the cable’s neutral conductor is attached to the earth stake. The technician will inspect the fuse base and then all the LV cables.

- Earth Resistance

This test is to ascertain that the max resistance level of the LV feeder is about 10 Ohms.

- High Voltage

This test, also known as the dielectric strength test, can be performed on either the AC or DC supply. In order to ensure the cable doesn’t short circuit, it is essential to carry out the short circuit test.

There are several reasons why high voltage testing is necessary on cables before being utilized. Most cables have been stored for extended periods and could have depleted in their original standard. A test would check for its usability and efficiency to avoid harm or damage.

How to Terminate High Voltage Cables

Terminating a high voltage cable is an essential part of cable installation, and there are various ways to go about this. One method is opening up a cable jacket and allowing the shield portion, which consists of the conductive, to be exposed. The cable’s insulating layer can also be cut back, thereby allowing access from the conductor to the connector.

It is easy to carry out the termination process by providing a conductive electric layer material that connects with the semi-conductive stress material. An insulating cover is applied over the stress control layer to facilitate a safer termination process.

Deciding on a single method to terminate a cable would almost be impossible, as the many techniques available all serve the same purpose. However, the two most widely accepted methods of terminating a high voltage wire include Cold Shrink and Heat Shrink termination methods. Most technicians opt for the heat shrink termination method to provide optimum stability for industrial use.

In conclusion, getting the right understanding of how high voltage cable is utilized and handled requires lots of education on the topic. High Voltage cables are capable of carrying out efficient services when adequately manufactured, installed, and fitted. This is why procuring the products of excellent hv cable manufacturers and trained personnel services are the best way to handle its installation.