How is MI Cable made? Mineral Insulated cable, abbreviated as MI Cable is a special cable that is designed with essential and critical circuit protection in mind. When it comes to critical electric systems, you don’t just use any cable. Currently, there are a few cables in the market that meet the industry codes and standards. One of the cables is the MI Cable, made from mineral-insulated technology as an alternative to polymeric methods or traditional construction.

In this article, you’ll learn about:

- The definition of the MI cable

- Its uses

- How it is made

- Whether you can direct bury the MI wire

- How to test the MI cable

Let’s dive right in.

1.What is MI Cable?

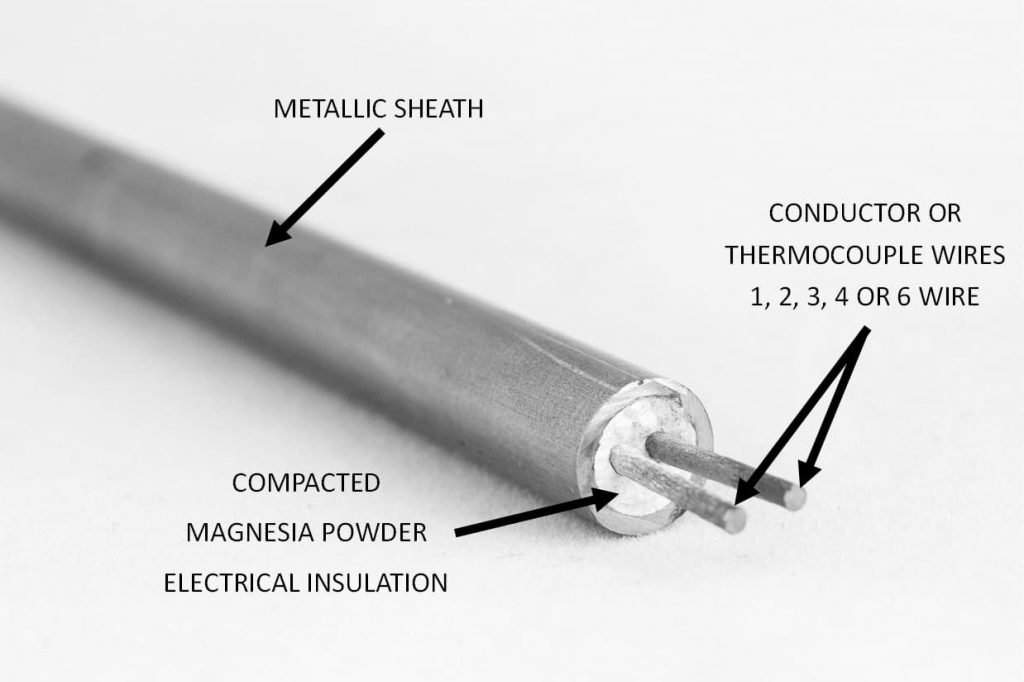

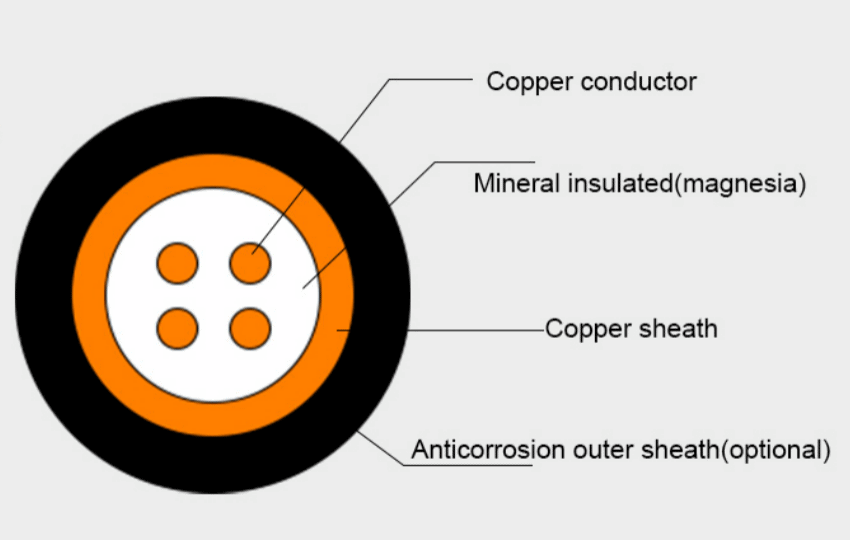

Mineral insulated Cables (MI Cable) are a specialized variety of cables made of copper conductors enclosed by an insulated metal sheath, made of resistant material like Stainless steel or Inconel. Inorganic magnesium oxide powder insulates the sheath (MgO). Inside the MI wire, there are conductor wires separated and insulated by the Magnesium Oxide powder.

Figure 1: A named MI Cable

In other terms, the MI cable is also called ‘Metal Insulated Metal Sheath’ (MIMS) or ‘Mineral Insulated Copper Cable (MICC). Colloquially, it is known as pyro.

If you need to build a highly effective fire survival electrical cable system, the MI cable serves the purpose adequately. In fact, it is the only cable in the market that survives real-world fire situations.

Here are some of its remarkable features:

- The MI cable provides more than 2 hours of escape time during ‘real world’ fire circumstances. In other terms, it is called the 2-hour fire rated Mi cable.

- It is the only certified cable to pass the modern furnace tests (test DIN 4102 1000 °C 90 mins and the German standard ISO834-1)

- It’s the only approved and listed cable by UL2196 due to its ‘unrestricted installation.’

- You can apply the MI wiring cable anywhere apart from environments that corrode or mechanically damage the copper sheath. If you have to use it for underground runs, ensure there’s maximum protection from physical damage.

- Due to its flexibility, you can twist and bend this cable around obstacles to any angle of your choice, provided you maintain the minimum bending radius.

- The Mi cable is used in fire protection applications like fire pumps, smoke control systems, and alarm circuits.

Overall, these cables are applied in high temperature and pressure environments because of various reasons.

- They resist oxidation

- Their inflammability is low

- They have a high insulation resistance

- They are easily bent to any form without causing short circuits

- You can easily seal these cables when using them as control or extension cables in critical places

2.What is MI Cable used for?

An MI cable is a unique cable used in environments with high temperatures due to its low flammability. Moreover, it is resistant to oxidation. Its metal sheath protects the conductor wires against oxidation when subjected to wet or chemically active environments.

Since the cable is inorganically made, it has nothing to burn, a reason why it does not contribute to further combustion. Further, the MgO is resistant to vapor transmission, flames, and gases within the object connected to the cable.

Thus, its corrosion resistance capabilities make the cable effective in areas where replacement and failure could be risky or even impossible. For instance, the MI cable is used by nuclear plants to keep an eye on temperatures. In such environments, it is extremely dangerous if the instruments for controlling temperatures receive inaccurate readings. Moreover, the environment is highly risky for repairs and replacements.

The MI cable is an excellent option for heating and power (it prevents and protects from fire in civil and industrial applications), in addition to electrical heat tracing (building and industrial processes).

In general, the MI cable assemblies are ideal for instrumentation, power, control, and thermocouple applications in designated areas. Its outer metal sheath is made of copper, which is approved to be a ground conductor. Moreover, the cable has a high current rating to meet all power applications virtually.

The MI cables are suitable for the following conditions:

- Fire and heat resistant

- Waterproof

- Temperature stable

- Radiation resistant

The MI cable does not degrade or weaken with age. Therefore, it lasts a lifetime.

Figure 2: A Colored MI Cable

.

Figure 3: Typical MI Cables

3.How is MI Cable made?

The Mi cable is constructed entirely of inorganic materials. The outer metal sheath and insulated conductors enable the cable to endure the harsh impacts of fire while being fully operational afterward. Here are some requirements to make the MI cable:

- Copper that is highly conductive-B5 or ASTM B4

- Pure Magnesium Oxide (MgO)

- A seamless Tube Cable

- A continuous and maximum operating temperature of 250 ºC

- Voltage of 0-300 volts AC/DC or 0-600 AC/DC

- Factory test voltage of 1500 volts RMS (300-volt cable)

- 0.1% power factor

- Dielectric constant (CIC) at 3.7

- Dielectric strength (70 volts/ml at 475 ºC)

The cable is designed to offer users permanent solutions to difficult wiring problems. It is made to enable its users to experience the comfortable and permanent installation of electrical circuits.

According to the MICC, a MI Cable company, the process of manufacturing the MICC cable requires several procedures;

-

- First, there has to be the best quality and pure Magnesium Oxide (MgO) powder. The powder is subjected to a melting point of 2800 C for it to be ideal for insulation.

- Second, the pure MgO is turned into blocks. Unlike other companies, the MICC manufacture the full range of MI cable.

- Thirdly, a seamless Copper Tube is used due to its optimal lifetime security and ability to withstand high pressure and stress. It is the perfect option for a fire-rated cable.

- Then, the required number of conductors is added, together with the MgO blocks.

- After that, the conductors and the MgO are inserted into the Seamless Tube Cable. The cable is then drawn through a die to make its diameter smaller and fit. The fine is highly tolerant to give quality via its unaltered geometry. Therefore, only cables with a perfect profile are produced.

- Next, the cable is annealed to get rid of the sheath stress caused by the drawing process. The drawing and annealing processes are performed repeatedly until a cable with the perfect size is formed.

- Here’s a video you can watch to understand MI cable manufacturing.

4.Can you direct bury MI Cable?

As an experienced engineer or contractor, you might be wondering if it is possible to direct bury the MI cable.

By now, you probably know the advantages of the fire-rated MI cable. You might have seen the cable in the field, and you’re still uncertain of installing it in your next project.

Worry no more. We understand your concerns because the mineral wire might be intimidating at first sight.

So, the organic construction of the MI cable gives it excellent capabilities to resist heat and fire. The cable can easily sustain heavy current overloads and high temperatures. Moreover, neither does it emit toxic substances, smoke nor allow flame propagation.

The fireproof abilities of the Mi cable make it the best choice for connecting various operations like:

-

-

- Motor operated valves

- Control stations

- Plant shutdown systems

- Other instruments that must be functional under live fire conditions

-

These cables are extremely reliable as control and power cables, especially in hotels, hospitals, fire pumps, alarm systems, and communication circuits.

A unique feature about the MI cable is that it never deteriorates at low temperatures. Moreover, it is never affected by extreme changes in temperature because the cable is solid and moisture resistant.

It is designed with an extruded metal sheath made of copper to make it impervious to liquids. Therefore, you can rely on the cable in any environment because neither corrosive solutions, water, or process liquids can affect it.

So, go ahead and make your move to direct bury the MI wire because it is extremely safe.

Figure 3: Various Parts of MI Cable

5.How to test MI Cable?

Before using the MI cable, you need to test it to ensure it has no direct shots.

Insulation Resistance Test

An insulation resistance test (RI) measures a cable’s total resistance between two points separated by electrical insulation.

This test aims to test the insulation material’s effectiveness; in other terms, it checks the quality of the insulation material.

Here’s how to conduct the insulation resistance test:

-

-

- Ensure your cable is clean and dry

- Conduct insulation tests before, during, and after installing the cable

- Record the test results in a table. You will get a sample table later in the article.

-

Required apparatus; Megohmmeter (500Vdc) and a heating cable.

Procedure:

-

-

- Adjust the voltage of the megohmmeter to 0Vdc

- Connect the negative lead to the tails of the cable.

- Connect the positive lead to the copper sheath of the heating cable.

- Link the negative lead to the cable’s tails.

- Switch on the megohmmeter and adjust its voltage to 500 Vdc.

- Subject the voltage to the cable and give it time to settle the reading.

- Any good cable will give you more than 200 MΩ of insulation resistance.

- If you get a reading below 200 MΩ, then the cable is damaged.

-

| Mi cable Insulation Resistance (Ohms) | |

| Before Installation | 320 |

| During Installation | 250 |

| Post Installation | 243 |

Insulation Resistance Test Cable Table

Last Updated on August 20, 2021 by Richard