Do you ever notice your life is not possible without electricity? What happens when you plug a device into the power outlet but nothing works? It’s time to brush up on your knowledge of cables.

Power and control cables export cables designed to carry electric current from one place to another. While they look similar, their design, construction, and usage differ.

When we see the two side-by-side, it can be hard to differentiate between the power cable and control cable.

But there are clear differences that distinguish them from one another. Power cables and control cables are both used to send electrical signals and power, but they are used for different tasks. This article will discuss the differences between power and control cables, their applications, and key features. Let’s dive in.

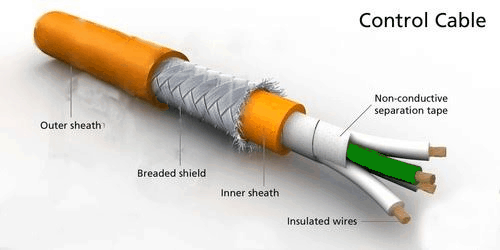

What Is A Control Cable?

Control cables are also known for their flexibility, durability, and resistance to noise interference. The insulation of these cables made from XLPE or PVC, or other materials gives them excellent flexibility and an ability to withstand harsh environments. Any control cable with multiple conductors must be color coded to distinguish the individual wires.

Also Read:The Astounding Features And Types Of Control Cable

Control Cable Types

Do you know what type of control cable is best for your application? With so many control cables available, choosing the right one can take time and effort. VDE and IEC standards specify the type of construction and materials used for each control cable. To help you out, here’s a quick guide to the most common control cable types:

KVV control cables are designed for switchgear and control panels in industrial and similar applications. The voltage rating of these cables is 600/1000 volts, constructed with stranded copper conductors, PVC insulation, and a PVC outer sheath. The conductor size ranges from 0.5 mm2 to 240 mm2, and the cable is available in various colors.

- KVVR Cable

KVVR cable is a control cable suitable for line electrical control equipment and instruments, monitoring and control circuits, electrical protection, and measuring distribution equipment. These cables are supplied to various industries and applications, including robotics, manufacturing, construction, electricity, and power distribution. They are common in both commercial and industrial markets.

- CY Cable

As a type of control cable, CY cable is the most potent and resilient of the three. It is designed for installations requiring high mechanical stress and vibration resistance levels. The conductors are bare copper, with XLPE insulation and a PVC outer sheath.

CY cables are often used in large industrial complexes, such as power plants, factories, or petrochemical sites where there is a need for heavy-duty protection against harsh environmental conditions.

- SY Cable

SY cable is a type of control cable that is used in commercial and industrial applications. Its low capacitance makes it ideal for high-speed data transmission applications. SY cables are often used in large buildings and factories because they provide superior mechanical, electrical, and fire protection.

- YY Cable

The YY control cable is the most robust, with an increased voltage rating of up to 1.5KV. It has a strong protective outer sheath and is designed for harsh environments. The copper conductors are individually insulated with XLPE insulation, which provides superior electrical properties. The cable is also flame retardant and resistant to abrasion, oil, grease, and chemicals.

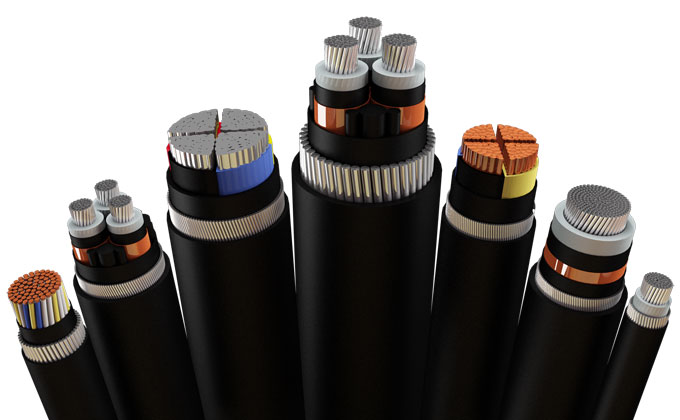

What Is A Power Cable?

A power cable, also known as a mains lead or AC power cord, is an electrical cable that carries the electricity from the main electrical supply to other devices. The cable typically has three components: a grounded plug, a wire that connects to the wall outlet, and a pin connector at the end of the wire. The power cable is insulated to transfer energy from the plug to the appliance.

Read More: A Guide To Choosing The Right Power Cable

Types of Power Cable

Marketplace offers a variety of power cables, from the traditional AC-type to USB and Thunderbolt cables. Your choice will depend on your device type and power delivery needs.

Low voltage cables supply power to equipment and appliances rated between 1,000 and 3,000 volts AC. This cable type is more common in residential buildings, as it provides a lower voltage than other cables.

You may opt for a medium-voltage cable if your appliance needs more power. These cables supply usually have a rating of between 3,000 and 45,000 volts AC. They are typically used in industrial applications, such as factories and laboratories.

You’ll often need even more power to get the job done. You’ll need to choose a high-voltage cable when that’s the case. These cables usually have ratings up to 150,000 volts AC or more and are used in power plants and other large-scale industrial applications.

Thhn wire is a power cable known as a building wire, or simply THHN. It is an electrical cable made up of multiple strands of copper wire insulated with a thermoplastic coating. Thhn wire has a higher current rating than other types, making it ideal for high-powered applications.

What Is The Difference Between Control Cable And Power Cable?

We truly understand your confusion when it comes to the difference between the control cable and the power cable. They are both very important components in any electrical setup and look almost identical, so it can be hard to know what’s what. The below points will help you to understand the difference between these two cables and why they are so important.

- Executive Standard

Regarding executive standards, control cable has its standard, and power cable has another. Control cables are designed according to the 9330 executive standards, while electrical power cables conform to the GB12706 executive standard. Usually, the executive standard defines the cable’s size, type, and quality.

- Core Color

Control cables are usually black with white lettering, indicating the positive and negative wires. The low-voltage power cable is generally color-separated for easy identification. To better understand the core color of each cable, check out the standard specified in your specific application.

- Cross Section

Control cables usually have a smaller cross-section, as they don’t carry as much current. The maximum size is usually no more than 10 square millimeters, while power cables can have sections of up to 500 square millimeters. With larger cross-sections, you must be more careful about selecting the right size for your application.

- Cable Core Number

To differentiate the core number of power cables and control cables, it is important to note that power cables generally contain a relatively small number of cores, typically ranging from single-core to 5 cores.

On the other hand, control cables transmit control signals and typically contain many cores ranging from 2 to 61 or more. Control cables use various core wire structures and shielding measures to obtain satisfactory electromagnetic compatibility effects.

- Rated Voltage

Power cables are designed to carry a higher voltage, ranging from 0.6/1kV and above.

On the other hand, control cables typically have a rated voltage of 450/750V. Ideally, it would help if you always used the cable rated for the highest possible voltages in your application, as this will ensure that it can withstand any overloads or spikes.

- Wire Sheath

The outer sheath of power cables must be robust and able to withstand extreme temperatures and resist corrosion. They also need good compressive and tensile strength, whereas control cables don’t require such demanding requirements. Regarding industrial power cable and control cables of the same specification, the insulation layer and outer sheath of the power cable is usually thicker than the control cable.

Difference Between Power Cable And Signal Cable

A signal cable is usually a low-voltage cable used to carry data or a signal. It is commonly used to connect computers, audio systems, and other electronic devices.

On the other hand, a power cable is a much thicker type of electrical wire that carries high voltages from one source to another. It is often used in generating plants and factories as it can handle high amounts of electricity and energy.

When choosing between a power cable and a signal cable, there are several factors to consider, such as length, voltage requirements, temperature ratings, etc. Both cables have their unique benefits depending on the job at hand.

Conclusion

Every transmission cable has unique features and characteristics, so knowing which type of cable is best for your application can take time and effort. Power cables offer advantages such as a reliable power source suitable for both AC and DC voltage applications, while control cables are more cost-effective and lightweight with excellent flexibility. The applications to both are relatively different, making it necessary to research and compare each option carefully.

ZW cable is the most trusted and reliable cable supplier in the industry, and we are here to help you make the best decision for your application. Your business should be supported by updated or inferior cable technology, so check out our wide variety of power and control cables. With the help of ZW Cables, you can rest assured that your cables are up-to-date with the latest advancements in cable technology.

Last Updated on November 27, 2022 by Richard