- Leading Cable and Wire Manufacturer-ZW

- Electrical Cable

Electrical Cables & Wires

- According to IEC 60502-1 and GB Standard

- Flame Retardant & LSZH Cable & PVC Cable

- Approved by GB, IEC, RoHS, SGS, BV

- Large stock with different sizes

- Rated voltage 35KV

Electrical Cable Size

Electrical Cables can be classified as low voltage cable, medium voltage cable, and high voltage cable. The raw materials for power cables are copper conductors and aluminium conductors. The armoured electrical cables are steel tape armoured cable and swa electrical cable. We have large types of power cables in stock.

Table of Contents

Understanding your choice of electrical cable options

Your choice of electrical cable may determine the success or failure of your electrical project. There are electrical applications that require specific types of wires. And then, there are applications where only specific types of cables, such as a 6mm electrical cable, will do. Substituting that cable specification for another, such as 2.5mm electrical cable, may destabilize the project.

In this post, we’ll explain the differences between wires and cables, and we’ll also discuss various types of cables and their uses. Hopefully, this information will lead you to make informed decisions about sourcing the right cables and wires.

What is an electrical cable?

When it comes to discussions around cable electric projects, you may see the term “cable” and “wire” used interchangeably. In terms of making general observations and discussing generic applications, especially by lay people (those not involved in the electrical field), there’s no harm in referring to an electric cable wire in this way. However, in a strictly technical sense, the two terms have starkly different meanings.

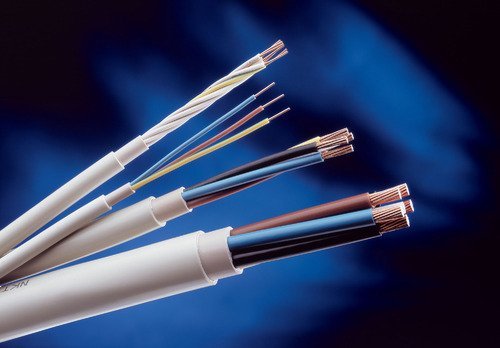

A wire consists of a single conductor, commonly made from either aluminum or copper. They (wires) come in two main forms. Solid wires comprise of a single conductor, and may either have a protective sheathe (colored); or the conductor may be bare (unshielded). Stranded wire is yet another type of electrical wire which typically holds several twisted strands of conductors inside a single sheath.

Leading Cable and Wire Manufacturer-ZW Electrical Wire According to IEC 60502-1, GB Class 6 Copper

When there is a requirement for higher-frequency applications with lower resistance, electricians choose solid wires. Stranded wires, on the other hand, make an ideal choice in applications requiring electrical cable wire with more flexibility. For some electrical applications though, wires may not be the appropriate choice. In such cases, electricians and engineers may find electricity cable the more useful choice.

So, what is a cable? Well, a cable is essentially an “extension” to a wire. It typically comprises of two or more insulated wires wrapped inside a single jacket. It is important to note that multiple conductors without insulation typically identify as a single conductor inside a cable.

So, as you can see, non-technicians may use the term wire and cable interchangeably, but the two words have different meanings to professional electricians. If you aren’t sure whether your application calls for a wire or a cable, make sure you consult a professional electrician first, before ordering or using a product.

What are the different types of electrical cable Wire?

The type of electrical cable is measured by the intended (or recommended) application. The measure of that application is the volts of power transmitted via the electica cable. Based on that measurement, these cables are grouped according to the following types:

A)Low voltage cables – transporting up to 1000 V: Typically, the coatings on these cables include thermoset and thermoplastic materials. They may be found in many residential and commercial applications.

This types of outdoor electrical cable also goes by an alternate name – 0,6/1 kV cable – and is used in many industrial applications, including infrastructure and industrial projects

B)Medium Voltage cables – for power range between 3kV to 36 kV: Typically, you’ll find this cable electric used in power distribution applications, including to transport power from an electrical sun-station to a transformer

C)High Voltage cables – for transmissions of power from 36 kV and above Because these cables handle extreme amounts of power, electrical engineers typically use a hv cable to transport bulk power from power generating plants to smaller local electrical sub-stations

D)Twisted pair cable – comprising of two cables twisted together to form a single cable

E) Control Cable– which has two or more insulated conductors running inside them

F)Electrical coaxial cable – that has an inner conductor and a parallel external foil conductor that’s protected by layers of insulation

G)Flexible cables are used to wire electrical panels and cabinets

H)Armoured Cables are used in applications where there’s a risk of aggression or interference to the cable.

I)Rubber cables are best used in applications requiring flexibility, such as stringing cables over uneven surfaces or around steep bends and turns

G)Halogen-free cables are useful in applications requiring low smoke and corrosive gas emissions in the event of a fire

Where there’s a need for electricity transmission in extreme conditions, electrical power cables are used

K)Solar cables are best used when connecting photovoltaic (PV) panels

L) Aluminum Cable: It is suitable and the best electrical wires and cables for electrical wiring in homes, airplanes, and power grids. The aluminum cable is a better conducting material than copper wire. It happens due to its electrical and mechanical qualities and lower cost.

M) Shielded Cable:A cable like an industrial electric wire cable has a common conductive covering around its conductors. Its primary purpose is electromagnetic shielding. The shielded cable reduces the volume and intensity of electrical noise. It also reduces EMI to eliminate negativity on signals and transmission.

N) UF cable: UF cable wires are encapsulated in solid plastic. This encasement shields each electric cable wire near me from the others. As a result, it prevents moisture or other external factors from entering the cable. UF wire is resistant to sunlight and suitable for electrical wires outside applications.

O) Flat cable: Compact electrical wire made of conductors and tubing designs are enhanced by flat cables. Again, home depot electrical is the best among electrical cable and wire manufacturers.

Electrical cables may also be identified in terms of their dimensions. For example, a 2.5mm flat electrical cable may be ideal for an application requiring cabling of a certain dimension. However, that size of cable may not be appropriate for another application, for which a 3 core electrical cable may be the right choice.

What Is the Difference Between Electrical Wire and Electrical Cable?

In this era, both the electrical wires and the electrical cables are essential properties in utility power installation. Hence, it’s very crucial to understand their differences in order to use them appropriately.

Electrical Wire

- The are made of a single conductor (AL/CU) which can be a solid or stranded type.

- Electrical wires, e.g., those used for earthing and connecting electrical apparatus and circuits are usually uncovered/bare.

- They are coated with a material that only gives prevention from deterioration and does not legitimize certify as electrical insulation.

- These electrical wires are sized by diameter, precisely via identification gauge numbers.

- Electrical wires consist of two main types: the solid & the high-grade ones.

Electrical Cable

- An electrical cable is made of two/numerous coated wires, enclosed in a comprehensive non-metallic or metallic shield for phenomenal prevention.

- These electrical cables are an autonomous wiring system and they do not need to be fixed in conduit.

- Unlike electrical wire, electric cable are standardized by sum number of wires which are constructed up of and their gauges

- They contain four main type: the Fibre optic, twisted pair, coaxial and multi-conductor cables

How Do You Identify Good Quality Electric Cable Wire?

Firstly, a high-quality copper wire and cable are made of high-purity oxygen-free copper and have a shiny core, while a poor copper wire and cable have a dull surface. Improper storage of the copper core cable causes oxidation. Therefore, evaluating the metal’s purity before you buy is essential. Since this can only be done after the receipt of the shipment, ZW cable and wire insist to all our customers that they should inspect and give feedback about the cable’s quality.

Secondly, auxiliary materials are used on some cables to ensure the cable’s roundness. A filler is added to the line core and the sheath to make it thicker. However, ZW Cables don’t have auxiliary materials to make them round and have very little filler with a thinner sheath.

Thirdly, for multi-stranded copper wire, during production, the flexible copper cable is bundled to improve the tensile properties of the copper core, its roundness, electrical properties, and the tightness of the insulator. However, most manufacturers omit this step since it increases the amount of copper used. ZW Cable recommends that to distinguish the two, you should cut open the core of the cable to see if the copper wire inside is stranded together.

Fourthly, if the cable breaks easily when bent by hand after being bent many times, ZW cables advise that it is likely made of low-quality recycled plastic and not virgin plastic.

Fifth, copper is a precious metal; therefore, if you need to measure the diameter of copper wire, you should use a micrometer. This is because even a slight loss in copper diameter can significantly impact the overall cost of various raw materials. Without a micrometer, it is possible to determine whether or not the wire is substandard by simply weighing the entire roll.

Alternatively, you might use the manufacturer-provided nominal weight. Some manufacturers publish a low weight that is too low, so they cannot guarantee the quality of their goods.

Sixth, ascertaining the cable length may be harder to identify since customers typically do not measure the number of equipment meters. ZW wire and cable use the same weight method to determine whether the cable is full meters. Printing the meter label at home or having it done at a factory is viable; however, labels with a diameter of less than 5 mm should not be printed. We reminds buyers the importance of inquiring of electrical cable price, the majority of cable producers have put cable wire price on their products.

What Is the Essential Covering Cable & Wires Color and Size of Wire?

It’s crucial to fully understand the insulation of electric cable wire colors and sizes for installation benefits. This is to make sure security and safety of fixers is encountered. So, this is the reason why electrical code needs and requests specific wires to contain particular color to ease the work. Hence, each electrical wire and cable color has its vital functions.

Green or individually insulated wires, including bare wires, are solely for ground wires. Equipment grounding cables ensure that fuses and circuit breakers trip open. Then cuts off the power flow in the event of a ground fault or electrical shock.

These bonding electrical wires for the house connect electricity to other metal systems in your home-ground such as gas piping, cable for telephone, TV, and plumbing pipes.

Hence, the black or red cable indicates hot wires that transmit electricity from the electrical panel to a switch. It also shows that electricity moves to appliances and other pieces of equipment. At the same time, the white cable shows neutral wires that complete the circuit. They carry the electrical current back to the panel.

With cables, the outer sheath contains much of the same information. This information may include the electrical cable wire manufacturer’s name, UL, or other safety certification marks. The sheath also helps know the voltage rating and size of the wires within the cable. Lastly, the sheath gives information regarding types of electrical cable and wire manufacturers dates.

The electric cable wire size chart differs depending on the use and amps. The standard electrical wire sizes are expressed in millimeters or American Wire Gauge. Example of, NM-B cable has different electric wire gauges, and their function include;

- Wire measuring 14-2 or 14-3 is suitable for grounding. Its general purpose is in lighting and outlet circuits (15 amps).

- 12-2 or 12-3 gauge of wire is suitable for use in the circuits for the kitchen, laundry, bathroom, and garage with 20 amps ground.

- 10-2 or 10-3 gauge of wire for laundry dryers and air conditioners, with 30 amps ground.

- 8-2 or 8-3 gauge of wire with 40 amps ground circuit are suitable for large appliances, electric stoves, and cooktops.

- 6-2 or 6-3 gauge with 55 amps Ground circuits is perfect for cooktops. The thermostat wire of this size is also ideal for air conditioners and big appliances.